High-end Chinese movements?

There is no hiding the elephant in the room whenever Chinese watchmaking is a topic of discussion. Distilled to its most fundamental state, the mechanical watch is an object defined by exactness in engineering. It is composed of a myriad of minute components interacting with each other in perfect harmony to power two or three hands; these serving as an indication of time. Reliability and precision are, consequently, of utmost consequence, and even before any external factors exert their pressures on the matter, when a country produces comfortably upwards of 50 million mechanical watches a year, more than a few eyebrows are inevitably raised— since quality and quantity are so often believed to be inversely related.

The sweeping structural changes in the Chinese economy of the 90s brought about a nationwide push towards mass production through to the early 2010s. This was reflected throughout the watch industry, with ensuing output being invariably characterised by sheer volume — of local calibres for the domestic market, clones of public domain Swiss workhorses and outsourced componentry scheduled for refinishing, assembly (and relabelling) all around the world. The easy reaction was to scoff at the possibility of a high-end Chinese movement, or at least one on a commercial scale.

But such is the expanse of China’s manufacturing landscape, that this emphasis on volume is a far greater reflection of prevalence rather than capability. And while the gap between their current output and that of the Swiss, Germans and Japanese cannot go unacknowledged, it is a gap that is closing rapidly — and, increasingly, one driven solely by social prejudice rather than material substance.

The Liaoning Peacock Watch Company

Enter the Liaoning Peacock Watch Company from Dandong, China. With history dating back to their founding in 1957, and a whopping output of 3.8 million units a year back in their 1980s heyday. They were at the forefront of the country’s initial watchmaking boom, and at one point, even earned a reputation locally for their eponymous city as the “Geneva of the Orient”.

The manufacture has since scaled its output back down to 1 million units annually. Instead of focusing entirely on cheap movements produced in great quantities, however, they have since recalibrated their offerings to focus on making the very best modern commercial calibres in the country, with a particular emphasis on developing their own unique configurations of higher-end complications such as tourbillons and chronographs.

This intent to push the frontiers of fine Chinese watchmaking can most recently be observed in the opening of a vast, brand new state-of-the-art facility in 2023, right beside their old manufacture in their 10-hectare Dandong Watch Industrial Park. With the company sparing no expense in outfitting their new headquarters, this facility has been decked out with a mixture of the very finest in Swiss, Japanese and Chinese watchmaking technology.

Our founders were recently invited to tour the new manufacture during its opening in July 2023, and they were blown away by the clinical conditions within which our movements are created, as well as the sheer beauty of the sprawling complex — replete with vast gardens, recreational tennis courts, and other such quality-of-life elements within it. We will have more content revolving around this visit to show you very soon, but in the meantime, a great friend of the brand — and one of Robin’s primary mentors, Mr. Ron Good, made a trip to the manufacture soon after. You can check out his experience here!

Peacock has been our primary movement partner from the very beginnings of Atelier Wen. What began with Robin and Wilfried showing up on a cold call to request for movements for the Porcelain Odyssey back in 2017 has since blossomed into a strong, lasting partnership. They have since given us unprecedented access to movement customisation and development, and we, in turn, are committed to helping them raise their standards and push their watchmakers beyond their current comfort zones in mechanical innovation and high-end finishing. In our experience, they have truly impressed us as the most forward-thinking and ambitious of the various Chinese manufactures, and our journey together thus far has led to the development of the current high-beat automatic movement you see in Perception today.

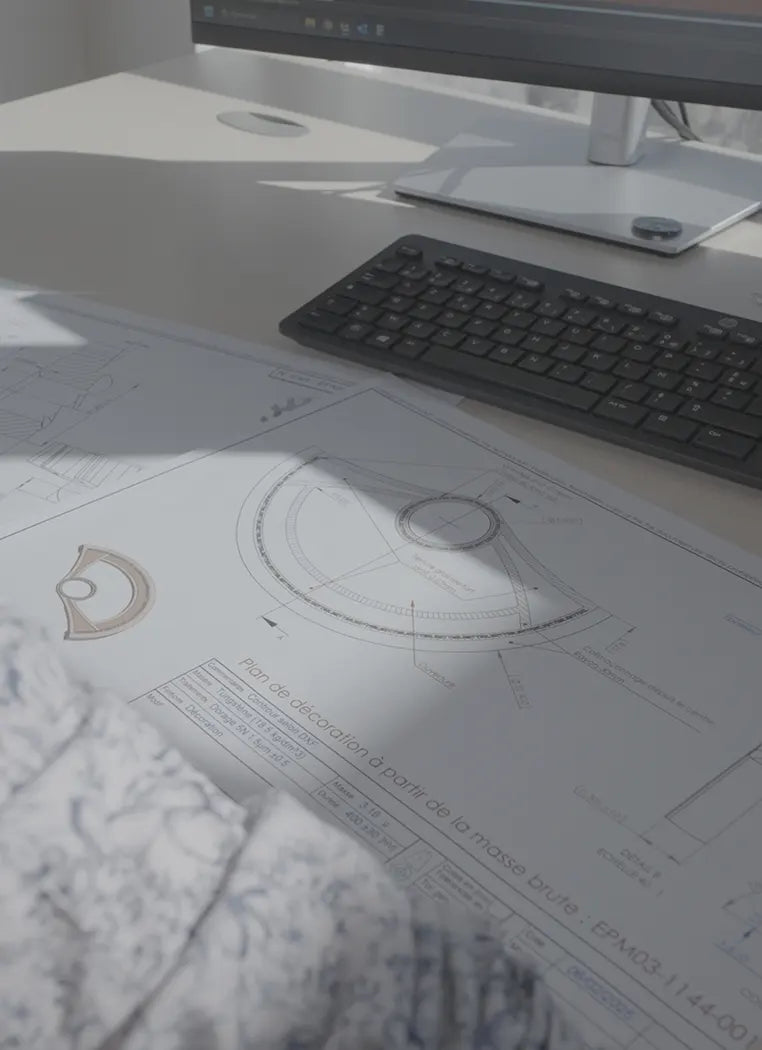

The beginnings of the SL1588

Which brings us to their original, extra-thin calibre, designated the SL1588. With Perception’s design intended to rub shoulders with the very best integrated sports watches in the field, we knew that one of the key requirements was for our watch’s profile to be as slim as possible. This was a taller task than anticipated due to the hand-turned guilloché dial housed within.

As the guilloché process involves carving material out of a flat plane of copper/silver, we were already confined by a minimum base thickness in which these carved lines would not compromise the integrity of the dial. Furthermore, our desire to achieve an exceptionally dynamic guilloché dial meant that we had to make an allowance for as much depth as possible — and this consequently necessitated a slightly thicker dial blank. In addition, the complex four-part 榫卯 (Sunmao) dial construction meant that the complete dial also took up far more vertical real-estate than most.

This meant that very few commercially available calibres would have allowed us to maintain Perception’s final dimensions outside of a handful of extremely expensive Swiss calibres from the likes of Vaucher and Lemania — and those simply would not do, given that we were committed to the idea of a completely-Chinese construction.

It just so happened that during the early stages of Perception’s conception, Peacock had recently completed the development of a new line of ultra-thin movements under the repurposed banner of the SL1 series (not to be confused with the original Liaoning SL1 movements from the 50s and 60s). At just 3.40mm thin, with a diameter of 27.00mm, it would allow us to incorporate both our complex guilloché dial construction, as well as slot seamlessly into the 40mm case of Perception. There were just a few little problems; the calibre in-question featured a date complication that we did not wish to disrupt the continuity of our guilloché dial with, the accuracy (+25/-15) and power reserve (38 hours) of the base calibre left much to be desired, and the default finishing was substantially lacking.

When we raised these points with them, Peacock were more than willing to accommodate us, and over the subsequent months, Robin and Wilfried worked closely with them to develop a higher-end variant, christened the SL1588! The aforementioned date complication was removed (along with the empty “ghost-date” position in the crown assembly), and the power reserve of the watch was extended to 41 hours and improved to a pre-regulation factory standard of +/-10 seconds. The movement finishing was also elevated significantly, and this revised calibre was granted to us in exclusivity — and has since served as the beating heart of Perception from its launch back in 2022.

The SL1588 in its very-earliest iteration — encased within our very first prototype of the Perception that we made.

The launch specifications of the SL1588 were much the same as they are today, with the aforementioned power reserve of ≥41 hours, a high-beat rate of 28,800 bph (4Hz), and a pre-regulation accuracy of +/-10s per day. The movements then undergo drop-testing and are adjusted in 5 positions, as well as in hot, cold, and ambient temperatures, before being observed for 48 hours prior to leaving the manufacture.

A hacking conundrum

Admittedly, we had initially sought one further addition to the calibre — which, until today, has been something we are often asked about, and that we have not yet been able to achieve. Based on some of the initial feedback Robin and Wilfried had gathered from before Perception’s launch, hacking seconds was fairly high-up on the wish-list, and though Peacock were game enough to attempt the implementation, they were ultimately unable to incorporate the function into the SL1588 at this point. Yet, while this may seem like a fairly simple feature to add to a modern movement, it is actually far more complex than expected in this particular instance.

In a nutshell, the main reason why the SL1588 cannot be easily hacked is due to its indirectly driven seconds hand. This style of seconds hand construction differs from most other modern calibres in its arrangement of the gear train — with the centre/second wheel, responsible for the driving of the minute wheel and hand, situated at the very centre of the watch’s movement. This necessarily offsets the fourth wheel — whose pinion is responsible for the turning of the seconds hand in a default small-seconds configuration. Historically this configuration has always held pride of place for the elegance of its mechanical simplicity — and it is still the arrangement of choice for many of the best watchmakers today.

Motion work of a clock, showing (f) center wheel, (x,b) cannon pinion, (x') minute wheel, (y,c) hour wheel, (t) hour hand, (m) minute hand. (Originally sourced from Tidens naturlære, 1903 by Poul la Cour, now in the public domain via Wikipedia Commons)

However, things get a little bit more tricky when reconfiguring this arrangement for a central seconds. In order for the seconds hand to be centralised, either an additional wheel or a pinion — that does not directly draw from the mainspring barrel’s flow of power — is required. To prevent this wheel from lifting from the main gear train assembly, spring tension has to be applied to hold it in place. In the case of the SL1588, this is achieved via a pinion rather than an additional wheel.

In contrast to this, most mass-produced modern movements relocate their fourth wheel into the centre of the movement by completely rearranging the gear train — and consequently, eliminate the need for an additional pinion/wheel and tension spring.

In a traditional manually-wound calibre, this would normally be the better solution since the absence of the additional wheel would translate to the thinner movement profile. However the SL1588’s use of a pinion instead of a wheel circumvents this, allowing the movement to maintain its slimness without this reconfiguration. This use of a pinion also allows for the entire gear train to be offset from the centre of the movement, thus making room for the centrally mounted tungsten rotor’s winding assembly to be better incorporated into the movement spatially, instead of being stacked vertically on top of the gear train.

The effective conclusion we came to here was therefore the forgoing of hacking seconds in favour of a slimmer watch. The addition of hacking — achieved by the abrupt application of friction to the balance wheel to stop it momentarily — is unfeasible within an indirectly-driven seconds system as it often lifts the spring tension on the aforementioned pinion, causing the seconds hand to behave erratically. This is not an issue unique to the SL1588, and many high-end calibres from celebrated maisons face the same problem — and to our knowledge, only one brand has found an effective solution to this with an elaborate, costly and patent-protected wheel which you can read about here.

Ultimately, we felt that the slimness in our movement was the more essential quality to maintain, especially given that the hacking function has no true bearing on a watch’s accuracy. But while this is not an implementation we can add to Perception for the moment, it is one that we will undoubtedly continue to explore and persevere towards!

The SL1588A: A 2024 facelift

Following the launch of Perception, our team sent out a meticulously-crafted survey to find out if — hacking aside — there were any particular improvements that you wished to see in future iterations of the watch. More than 400 of you responded, and after spending a great deal of time compiling and compartmentalising the feedback, one of the points that seemed to frequently crop up was the desire to see more of our movement.

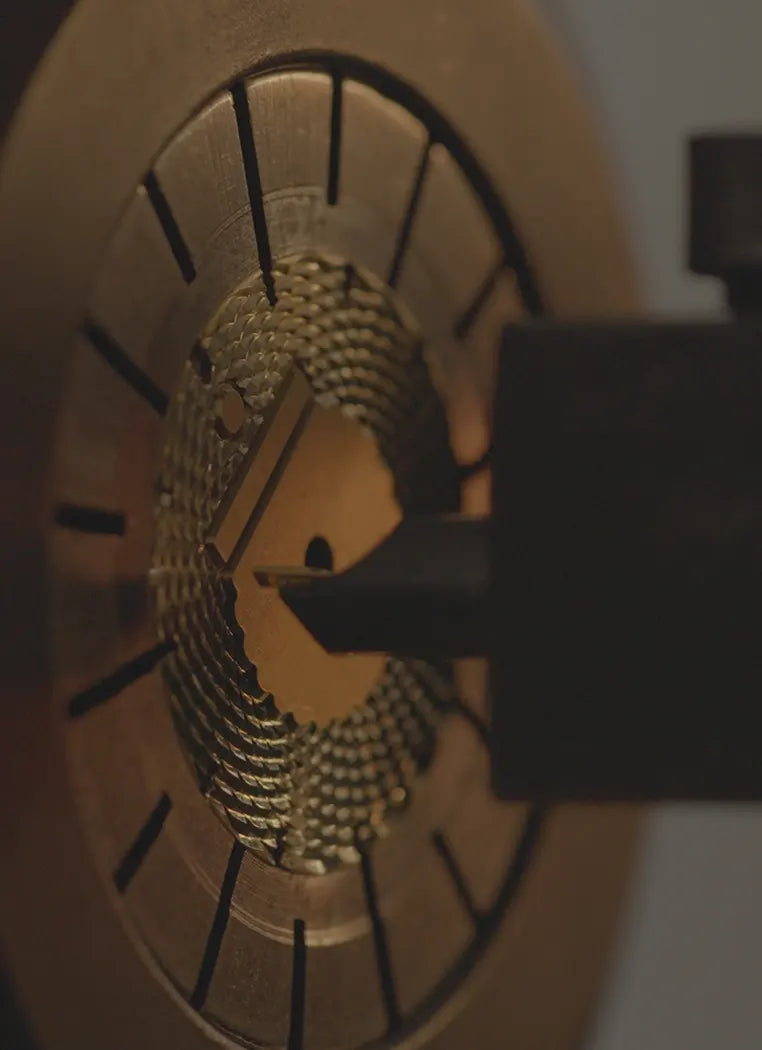

While the SL1588 was already a well-decorated movement, relative to its volume of production, the decorations applied were nonetheless industrial, and largely the result of machine-finishing. Our founders were therefore insistent that the case-back would not be fully opened until we truly incorporated a movement that was worthy of such an implementation. And yet, as watch lovers themselves, Robin and Wilfried wanted the little window within the 石狮/stone lion’s mouth to give as much horological joy to its wearer as possible.

Despite the watches having only been in production for just over a year, we therefore resolved to implement some custom adjustments to the finishing on the movement — which Peacock once again graciously accommodated with the SL1588A. Where previously, the main finishing on the movement’s bridges had been a straight côtes de Genève (Geneva stripes), these are now executed in circular côtes that align perfectly with those on our black rhodium-plated rotor.

To complement this, we have also deepened the anglage (chamfering) on the edges of all the movement’s bridges, alongside beautiful, deep, golden engravings demarcating our brand name and the adjustments that the movement has been put through.

And we did not stop there! The screws, previously just mirror-polished, have now been given a beautiful heat-blued surface, and each jewel and screw has also been surrounded by the halo of a polished sink; an element rarely seen in watches at our price-point.

The main plate — that is decorated with perlage (pearling) — has also been deeply engraved with serial numbers that help us better-track each individual movement. Beside these engravings of the serials, we have also carved our logo into the baseplate beneath the escapement to more expressly indicate that this movement has been created specially for us. We have also taken additional steps to ensure that the antishock system on the escapement jewel is now perfectly aligned in the direction of the the balance bridge.

The final change surrounding the movement has been the addition of one further step in our quality control process. Whilst we had already implemented several stringent stages in regulating and testing the individual movements since the earliest days of the SL1588, the assurance to our customers of our movement’s reliability is something that we will not ever take for granted. We have therefore partnered up with China’s Horological Research Institute of Light Industry (HRILI) for a further round of random testing following assembly for the SL1588A. As China's top national research lab, HRILI are responsible for the drafting of the country’s equivalent of ISO standards in watchmaking and timekeeping, and also bear the immense responsibility of conducting all precision-equipment assessments in China’s national space programme.

Into future of Chinese watchmaking

As we continue to develop subsequent calibres — both in continued association with Peacock and with other manufactures — you can be sure that we will continue to wear the Chinese-made label on each and every movement as a badge of pride

While the rest of the world may not yet be of the same opinion, the proof is in the pudding that high-end, exceptional Chinese watchmaking is already very much a reality.

Just as we continue to champion Chinese craft and culture, the movements that power Atelier Wen’s timepieces will seek to reflect and celebrate the very best that can be found in China. And in doing so, we hope to wholeheartedly express that quality is far more a question of individual and collective effort than it will ever be of origin or geographical place.