Backdrop

In the aftermath of an exhausting manufacturing and delivery phase, our first Perception batch was delivered in January 2023. Despite the positive sentiments that these early watches were largely met with, we nonetheless sat down to once more review what we had just let loose into the world.

The batch took everything we could muster at that point, and while we were confident it was good, we were sure we could do even better; that there were still small aspects of the watch that could be further refined in its subsequent iterations. This commitment to continuous improvement was something we wanted in our DNA from the very beginning, and with the wonderful community that was growing around the brand, it was a real opportunity to get a whole lot of qualified feedback from beyond the bubble we had been working within during the final stages of Perception’s development.

While we could have simply dissected the V1 ourselves and implemented what we felt was best for its development, it was essential to us that any sense of what could be improved upon was contingent on — or at the very least, informed by the perspectives of our community. You are, after all, the ones who wear Perception from day-to-day, and if there were elements that we missed out on, they were sure to be picked up by you!

The feedback that came back took several weeks to sort through, with more than 400 responses; many of which comprised of essay-like answers that balanced praise of the series with necessary and well-appreciated constructive criticism. We asked, you spoke, and we listened, sieving through the comments and taking note of the individual pain-points which we then acted on. Robin and Wilfried then headed up to China to align on all those points with our partners and suppliers over the course of summer 2023.

It is the most pertinent of your comments and feedback that we hope to answer with these new updates to the series, and we hope to continue this vein of responsiveness to your voices long into the future of our brand.

Your feedback (and some of ours).

So what exactly were the most pressing suggestions that you had? We have laid them out in a list here, paired with the steps that we have taken to address them!

1. The bracelet finishing and execution was slightly lacking compared to the case.

From this batch onwards, we have improved the quality of the bracelet finishing, introducing hand-finished chamfers on all the inner edges of each individual link to create a more elegant visual effect. Alongside this, we have introduced a greater taper (from 22mm to 18mm), as well as a gradual thinning of the bracelet from the lugs to the clasp (from 3.0mm to 2.6mm - down from 3.2mm on all the links on the V1).

In order to accommodate these changes, Perception’s case was also necessarily remoulded, with the lugs now featuring a more pronounced taper.

2. The clasp blade was too long, making it less-ideal on smaller wrists (this was particularly apparent on the titanium models due to the material necessitating a stiffer flex).

In order to improve the wearability of the clasp, we have developed and introduced a telescopic clasp blade that enabled us to reduce the length of the blade by more than 1/3, thus greatly improving the way it rests on the underside of the wrist, whilst still ensuring that your hand can easily slip into the circumference of the bracelet when the blade is extended.

The brand’s signing on the clasp blade has also been newly-executed in CNC, with a textured backdrop that accentuates it far more apparently than before.

The clasp was also further thinned to match the new bracelet, whilst retaining our proprietary micro-adjust mechanism.

3. The case-back’s stone lion motif was a little bit flat/one-dimensional.

While far from a pressing change — given the prevalent praise that our Shí Shī has enjoyed, we nonetheless chose to implement a completely new hammered-texture around it, creating more contrast and making the lion appear even more three-dimensional.

Like the clasp blade, we have also switched our process for all case-back text to be executed in CNC, where it had previously been achieved via acid etching. The words themselves are therefore now three-dimensional, rather than merely etched into the surface of the case-back.

While not called-for by the survey results, this was our own little nod to the late Kiu Tai Yu, the father of independent watchmaking in Hong Kong — with this treatment of case-text being one of his hallmarks. And though it necessitated us going to the effort of creating unique CAD files for each individual case-back, we felt it was entirely worth it for the visual improvement, as well as the meaningful homage that it paid.

Image — SJX Watches

4. The dial was not as good as Voutilainen’s.

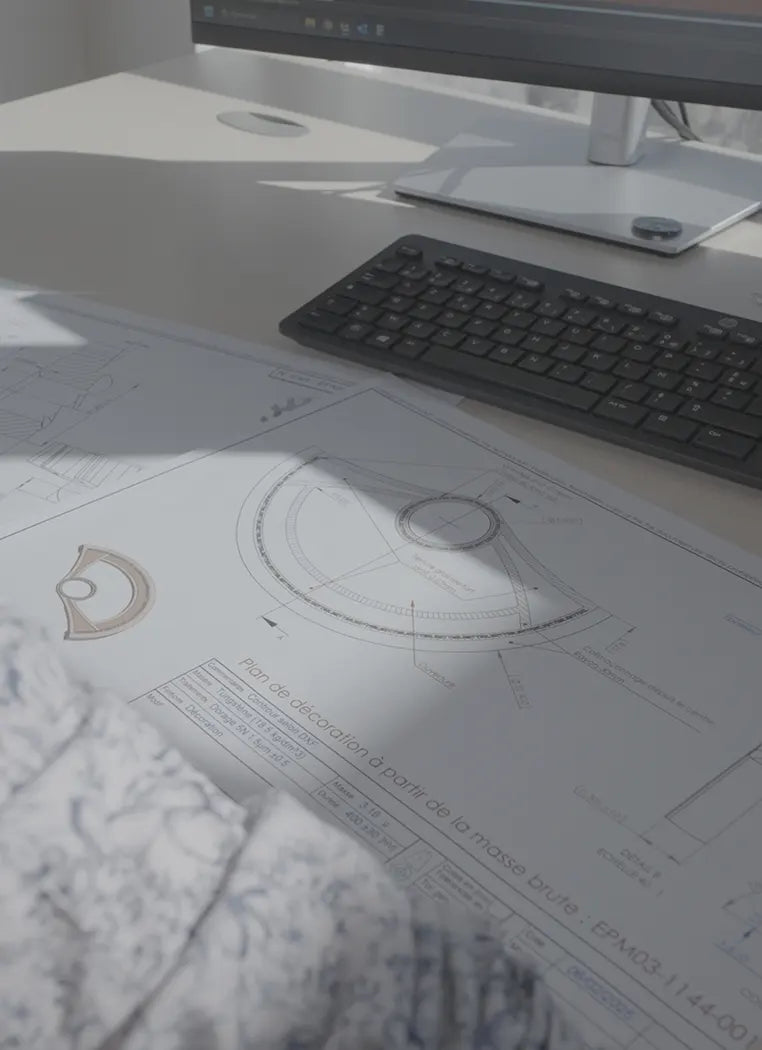

This is, of course, a little bit tongue-in-cheek, but while it was not exactly something impressed upon us in the survey responses, the dial work of Perception has unquestionably come a long way since we first began working with Cheng thanks to the practice he has had with our continuous purchase of his annual output of guilloché dials.

He has also been able to fund the construction of more rose engines and the training of several new apprentices, with some of the older ones well on their way to mastering the craft in their own right.

5. The seconds hand had initially experienced some overcompensation in amplitude that was caused by its centre of gravity to be slightly off-balance. While they were nicely finished, they were also a little bit too flat.

We completely remodelled the hand to extend and reshape the counterweight, giving it more volume and length to simultaneously improve its centre of gravity and its overall aesthetic. In addition to this, we also redesigned both the hour and minute hands to match the new voluminousness of the seconds’ counterweight, making them far more sculpted than they were before.

6. The lume on the hands was not bright enough.

While we were already using Super-LumiNova in the V1, we found a way to add more lume in the hands, as well as adjust the formula to amp up the brightness and duration of the lume.

7. The movement was Chinese-made and customers needed more assurance.

We have implemented new and rigorous testing measures with the Horological Research Institute of Light Industry (HRILI). While perhaps an unfamiliar name outside of China, HRILI serves as China’ s premier national-level horological research institute. Founded in 1963, it is responsible for the equivalent of ISO standards in China, as well as for the testing of precision timekeeping equipment in their national space programme, among many other things.

8. Many of you wanted to see more of the movement.

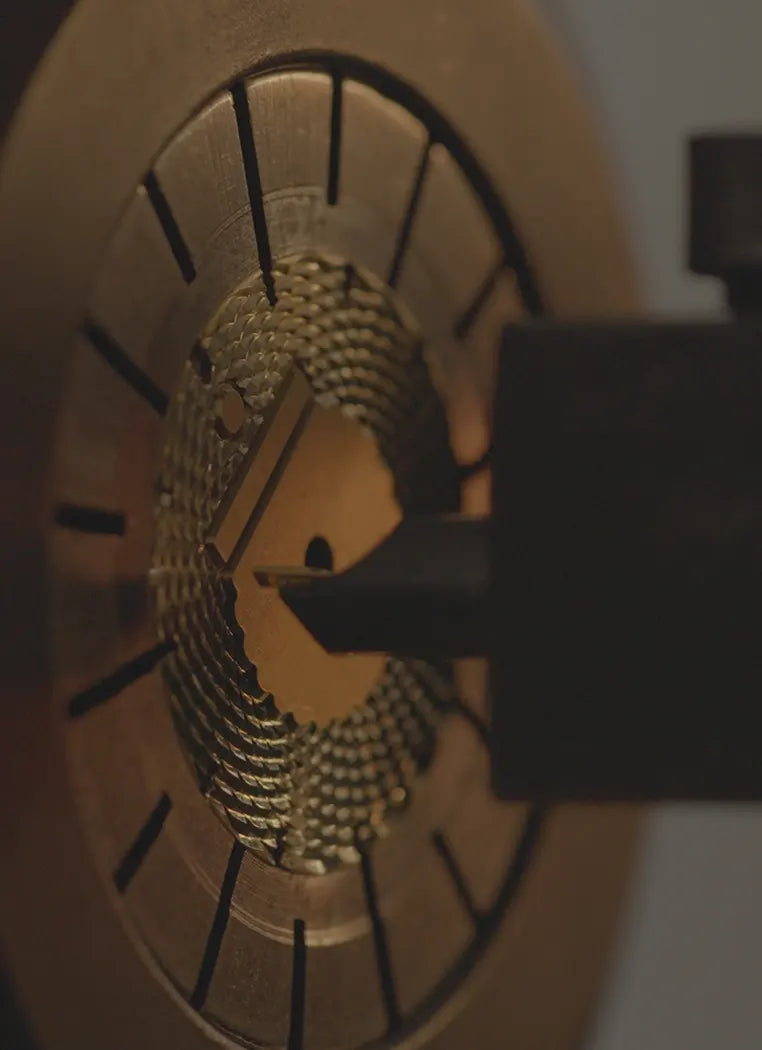

The quality of the SL1588's finishing is already notably high relative to its immediately comparable peers, and this (alongside its reliability and sturdy construction, as well as Dandong's openness to allow us to customise it) were key factors in us adopting it for Perception. This led to many of you asking us if a fully-open display case-back was a possibility.

While Perception's concept — being framed around architecture, meant that our 石狮 was not going away, we decided to nonetheless give those who requested for it something to shout about! In this iteration of Perception, we have therefore sought to further improve what you see within the little window of the lion’s mouth — as well as everything else that you don’t see. The movements have therefore been completely refinished, now-decorated with a circular côtes de Genève with more pronounced anglage than before. We have also elected to include little elements of handiwork to complement this — including polished sinks around the screws and jewels, as well as the introduction of heat-bluing on the screws.

The movements from this batch onwards will also be individually numbered by-batch to more reliably track each batch of watches going forward.

9. The rubber straps were too long and were not as comfortable as they could have been on small wrists — with their clasps being too thick and their deployant blades too long.

As one of the most prominent criticisms that we received, we knew we had to act to ensure that the supple FKM straps were actually wearable for all wrists. To resolve this, we created new moulds for the straps to shorten them and make them more wearable.

In addition to this, the deployant clasps were redeveloped to be thinner and more in-keeping with the refinement of the watch head and bracelet. They have also been given the same telescopic deployant blade as the bracelet, further enhancing their new-found wearability.

Perception is only a year-old… So why now?

Given the relative youth of the series, as well as the fact that the vast majority of customers had little-ill to speak of its debut batches, we could indeed have spared the immediate expense and left these improvements to a later date. This would have held-off on expensive tooling, remoulding and development costs so soon after the launch of the model, and given us more certainty and assurance in our cash-flow.

However, while that is perhaps the route most other brands might have chosen to take, it was not in our nature to sit back and wait when we knew we could deliver a better product by pushing those changes through. We also see the endeavour of Atelier Wen as one in constant evolution, and that as good as each release might seem, it can never be assumed to be perfect. This philosophy is one that has served us well thus far, with a supportive and constructive community developing around the brand, and if we hope to pursue the dream of becoming the finest watch brand of Chinese-origin, it is a philosophy we absolutely have to abide by.

With the switch to a deposit system and the adjustment to Perception’s price due to our significantly inflated manufacturing costs, we also wanted to ensure that the trust that you have continued to place in our watch and brand was suitably rewarded without compromise.

And though these additional implementations and costs might necessitate a more-careful, more-prudent management of our immediate projects and expenditure, they are unquestionably worth it to us in guaranteeing the longevity of Perception as a mainstay of our brand, as well as a further representation of our commitment to giving you only the best that we can offer at any given time! :)

Perception V2 Update List

Case

- — Re-moulded lugs with a more distinct taper from the case to the lug-tips.

Case-back

- — Brand new finishing on the case-back including:

- — Hammered texture surrounding stone lion motif.

- — CNC-engraved, 3D lettering on all text (previously acid-etched).

Bracelet

- — Individual chamfers on all links.

- — Improved taper from 22mm at the lugs to 18mm at the clasp (previously 19mm).

- — Gradual thinning of the bracelet from lugs (3mm) to the clasp (2.6mm) — previously a uniform 3.2mm throughout.

Clasp

- — Thinner clasp to match above bracelet improvements.

- — Newly-developed telescopic deployant clasp blade for greater wrist-comfort.

Hands

- — Added volume with curved upper surfaces and improved finishing on the hour, minute and seconds hands.

- —Remodelled counterbalance on the seconds.

- — Increased quantity and quality of Super-LumiNova X1 formulation.

Movement

- — New movement finishing including

- - Circular côtes-de-Genève (previously regular côtes)

- - Improved anglage

- - Polished jewel and screw sinks

- - Heat-blued screws

- — Individual numbering on each movement batch.

- — Implementation of new rigorous testing measure with the Horological Research Institute of Light Industry (HRILI).

Straps

- — Remoulded, thinner rubber straps with more pronounced taper (22mm at the lugs to 18mm at the clasp (previously 19mm).

- — Telescopic deployant blade system.

- — Newly remodelled, slimmer deployant clasp.