Here at Atelier Wen, we take invariable pride in each and every release that we unveil. This, however, is one that we are particularly proud of.

The Atelier Wen Inflection launches as our permanent flagship collection. It features an unprecedented construction of 99.9% pure tantalum throughout its case and each individual bracelet link, a grand feu enamel dial by the Beijing workshop of Mr Kong Lingjun, and a customised Girard-Perregaux 03300 calibre.

It is a release that has occupied us for the better part of the last three years, and the majority of that time has been spent developing and refining our capabilities with the rarified metal that is tantalum.

A material that has long held notoriety within the watch industry, tantalum is perhaps best known for being vexatious to machine and almost impossible to finish. Yet, its substantial density, prized bluish-grey tone and enigmatic sheen when polished have seen it attain near-mythical status. A permanent, serialised release of bracelet watches in full-tantalum has never been realised, until now.

Inflection arrives in three separate variations:

— 幽 (Yōu), our limited launch edition with a fumé, translucent grand feu enamel dial ranging radially from a pale green to a rich viridian, on a hand-hammered 925-silver dial base. It is complemented by white Arabic numerals and voluminous, bi-planed, rhodium-plated hands.

— 墨 (Mò), a first permanent variant with an obsidian black, grand feu enamel on a 925-silver base and featuring gilt Arabic numerals and voluminous, bi-planed, 5N rose gold-plated hands.

— 渊 (Yuān), our second permanent variation with a midnight blue grand feu enamel on a 925-silver base, and featuring white Arabic numerals and voluminous, bi-planed, rhodium-plated hands

These will be confined to a small annual production of just 100 pieces across the 3 variants. The launch edition, 幽 (Yōu), is limited to a numbered edition of 30 pieces, and will be permanently discontinued once sold out. The remaining 70 pieces of in the first year of production will be divided according to demand between 墨 (Mò) and 渊 (Yuān).

The watches are expected to deliver in late-Q3/early-Q4 2026. Allocations will be conducted on a-by application basis, and more details can be found here [link to PDP].

THE ABSOLUTE EXPRESSION OF OUR FOUNDERS’ AMBITION

Inflection was born out of an overwhelming desire to realise an underlying goal of Atelier Wen that Robin and Wilfried had quietly held since founding the brand in 2018: of one day creating a watch that was free of any restraint or constraints, whilst standing toe-to-toe with the very best in our industry.

The launch of the Porcelain Odyssey had, at the time, already represented a significant and ambitious release from a Chinese micro-independent. However, in our founders minds, it had always fundamentally been intended as a proof-of-concept; a litmus test to determine collector appetites for increasingly qualitative watches of Chinese origin.

Even as those porcelain dials sold out and were discontinued, and their successor, Perception, brought the brand more recognition, Robin and Wilfried never lost sight of that dream. In the wake of Perception’s immense launch success in 2022, they began discussing what this picture of ambition could look like — and it did not take long for them to begin looking seriously at the enigmatic material that was tantalum.

Before the watch world had caught on about a certain blue-dialled tantalum dress watch, Robin had long admired the metal’s unique, mysterious tone and captivating density. While he never found himself in a position to add a watch in tantalum to his collection, his appreciation for the material and its notoriety in baffling even the finest watchmakers quickly grew into an obsession. And as the metal entered more prominently into the consciousness of collectors around the world, we set to work pouring efforts and resources into developing our capabilities with the metal.

This process kicked off early in 2022, and certainly did not came without its pains. When we first began trials in machining and finishing tantalum, only a handful of manufactures in China had ever attempted to shape the metal to these purposes. None of them had ever pursued the degree of finesse we were asking for, nor attempted to fashion the metal into a bracelet. Some were willing to try, but very quickly backtracked on their initial enthusiasm after finding out just how difficult the process was. In total, we began research and development around the metal with eleven separate partners in China, and within a matter of months, that number was whittled down to just two.

TITANIC, TOILSOME, TANTALISING

Tantalum derives its name from the Greek demigod Tantalus — who was tormented by the gods to stand within a pool of water beneath a fruit tree. Each time he made an attempt to reach for the water or fruit, they would recede beyond his reach, leaving him perpetually thirsty, but unable to quench that thirst.

The metal’s discoverer, Anders Gustaf Ekeberg, first observed its extraordinary aversion towards typical reactions when contacted by acids (and its unquenchable ability to seemingly absorb said acids) in 1802. He likened this quality of perpetual longing and unquenched thirst to Tantalus’ relationship with the water and fruit, and thus christened it after the demigod.

This same logic of aversion and resistance could well be applied towards tantalum’s relationship with machining. The metal exhibits a “gummy” or “sticky” behaviour that inhibits precise tooling during traditional forms of reductive manufacturing. Furthermore, its high melting point (3017°C) and relative hardness (6.5 on the Mohs hardness scale) prevents it from being easily moulded or machined, and ruining all but the most specialised of tools.

In one of the most comprehensive, contextualised explorations into tantalum’s use within the watch industry, Revolution Media’s Cheryl Chia notes that:

"[TANTALUM’S] HIGH MELTING POINT GENERATES SUBSTANTIAL HEAT DURING MACHINING DUE TO THE LARGER CUTTING FORCES REQUIRED. IN CONTRAST, METALS WITH LOWER MELTING POINTS ARE GENERALLY EASIER TO SHAPE AND MOLD. THE EXCESSIVE HEAT, IN TURN, LEADS TO RAPID WEAR AND DAMAGE TO STANDARD MACHINING TOOLS, WHICH MUST WITHSTAND THESE EXTREME CONDITIONS. FURTHERMORE, TANTALUM HAS RELATIVELY LOW THERMAL CONDUCTIVITY (~57 W/M·K WHILE PLATINUM IS 71 W/M·K), MEANING THAT WHILE IT CAN CONDUCT HEAT, IT DOES NOT DISSIPATE IT EFFECTIVELY. THIS RESULTS IN LOCALIZED HEATING, FURTHER EXACERBATING TOOL WEAR."

Her article goes on to interview several of the finest and most revered names in watchmaking, with each sharing their anecdotal frustrations in working with tantalum.

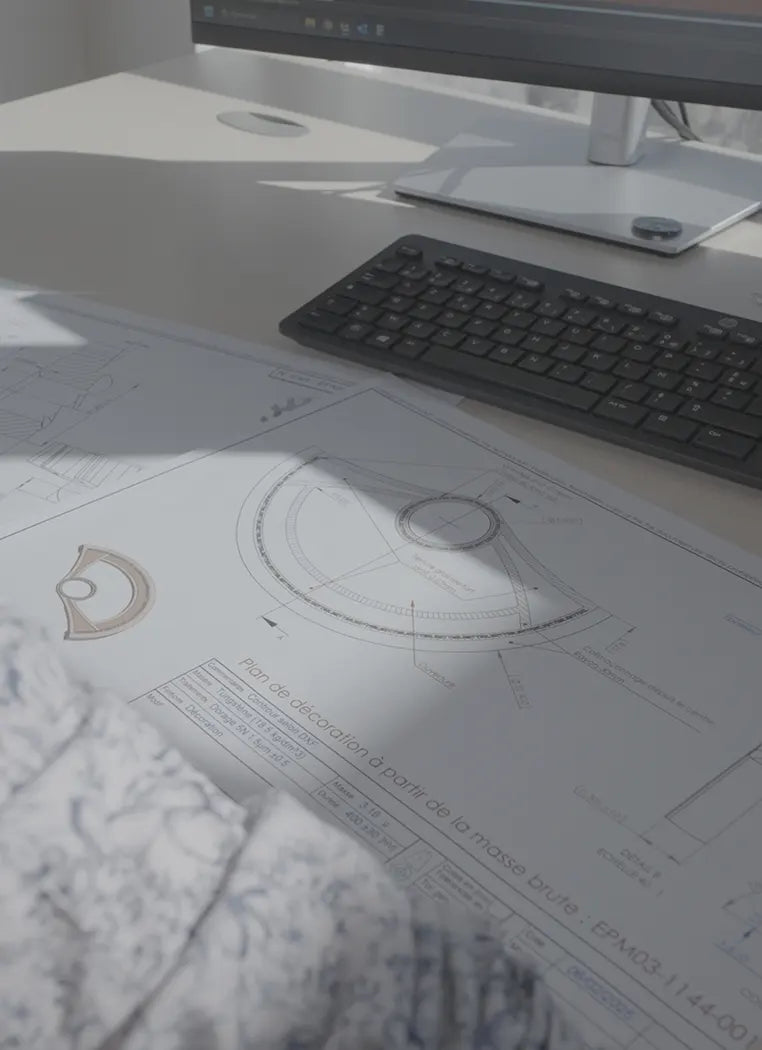

Needless to say, our pursuit of this project posed many complex challenges for our chosen manufacture, since they had never previously worked extensively with the metal. The trials stretched on, until we finally made our first significant breakthrough in early-2024, debuting two singular prototypes of Perception in tantalum during the year’s edition of Watches and Wonders.

While these initial prototypes were never meant to be released commercially, we made and brought them along with us to Geneva for two very specific reasons. The first was that while we had researched and largely affirmed our manufacturing assumptions that these tantalum bracelets could be made, this was something we needed to validate for ourselves with actual, physical prototypes. We also wanted to ensure that the integrity of some of their features (including the bracelet pins and clasp) were robust, reliable and ready to be translated into an actual release down the line.

The second reason was, admittedly, more to prove to both ourselves and our naysayers that this project was more than just a pipe-dream. Up until we unveiled those two prototypes in the metal, only three individual, unique examples of full-tantalum bracelet watches were publicly known to exist. As such, when we first shared our initial plans for a serialised, full-tantalum bracelet privately, many reacted with incredulity and general disbelief that a small Chinese brand could hope to pull off what some truly big names had previously tried and given up on. The prototypes were therefore debuted as a proof-of-concept, providing irrefutable evidence that the material achievement was something that we could and had achieved, and that we were more than serious about bringing this dream to market.

The aftermath of our exhibition saw us overwhelmed with requests for the availability of the metal. And while those requests partially found form through our 25-piece limited collaboration of Perception '鸿' (Hóng) with Grail Watch, as well as the three “tantalum tickets” that we delivered with our Millésime, 睦 (Mù), we had already known then that our intentions for the metal were far more ambitious.

THE MASOCHISM OF CURVATURE

If machining and finishing tantalum were not already enough of a tall order, Inflection’s design dials that difficulty to eleven. In the rare instance that tantalum forms the material of choice, achieving fine brushing and, more significantly, mirror-polishing on its surface is tremendously difficult even on flat planes. Inflection’s case and bracelet contains none of those. Instead, every surface on the watch has been rendered convex or concave, forming an intricate interplay between positive and negative space throughout its profile, and an exponentially more difficult task to finish.

To further complicate things, these surfaces are not finished in uniformity from one to the next. Finely brushed “H-links” give way to mirror-polished, concave chamfers along each edge, with similarly-polished, voluminous mid-links contained within them. Each curved surface presents a new and altogether different challenge, with different polishing approaches and tooling required for both concave and convex curvatures, and this once more varies depending on their radii. Achieving the desired degree of consistency and refinement in the polishing of these took almost three whole years of development.

Yet, despite these difficulties and the excessive costs involved, the pursuit was one we deemed essential to the release. These complex surfaces were specifically designed to capture the natural sheen and beauty of tantalum, with its dark, bluish-grey hue being far more apparent on curved and polished areas. The consequent drape of the bracelet also translated to a highly comfortable experience on-wrist despite the material’s weight, and was something that we refused to compromise on considering the level of ambition and elevation that the project represented.

This sense of elevation comes precisely from our dramatic shift towards curvature. Where Perception embraced flat planes and sharp angles, Inflection is an exploration of this multitude of curved surfaces, and the noticeable absence of straight lines.

When our designer, Alfred Chan, first began conceptualising Inflection, he approached it from the perspective of continuity, since our previous releases had collectively served to establish the beginnings of an overarching design DNA for Atelier Wen. Even as we strove to place Inflection above its predecessors, we wanted it to remain a natural evolution of our brand's core through familiar design cues and expressions that were emblematic of the brand. This proved to be a significant challenge; Alfred had to reinterpret our established design codes, striking a delicate balance between the familiar and the new.

The final design of Inflection draws its frontal profile and base geometries from the familiar shapes of Perception, and keeps the distinctive leaf-shaped hands and 回纹 (huí wén) that have become calling cards for the brand. Yet, the look and feel of the overall timepiece is markedly different and significantly elevated from the watches that came before it.

These curves were not a mere aesthetic decision. Instead, they tap into the prominent Chinese philosophical concepts of 阴 (yīn) and 阳 (yáng), and emphasise on a complementary duality and harmonious interplay between opposing qualities that are found throughout the watch.

The watch exhibits its various elements in pairs, with each aspect possessing a corresponding, synchronous reflection of the other that echoes this philosophy:

The complexity and thoughtfulness of their interactions is further established through the deliberate superimposition and cross-element pairings of the 阴 (yīn) and 阳 (yáng) elements:

— The brushing (yīn) on the convex (yáng) surfaces

— The polishing (yáng) on the concave (yīn) surfaces

— The weight and visual depth of tantalum (yīn) on the external construction (yáng) of the watch

— The symbolic lightness and airiness of the wind-inspired, wavy côtes on the movement bridges (yáng) on the internal underbelly (yīn) of the watch

Inflection as a whole is therefore a physical manifestation of this ancient idea — of two halves that interact to create a perfect, harmonious whole.

The significance of these concepts of duality and balance are not merely philosophical, but ones that extend throughout the narrative of Atelier Wen’s journey as a brand. The cultural duality of East and West was what first united Robin and Wilfried in shared purpose, and they themselves work in tandem as two complimentary halves: Robin as the creative visionary and Wilfried as the grounded, commercial mind. Inflection (and the ambitious and trailblazing spirit that led to its creation) is therefore emblematic of far more than just being our new flagship release. It encapsulates the very essence of Atelier Wen; all our idealism and aspiration, as well as the effort and industry, that have been poured into it over the 7 years since its creation.

DIALS BY CHINA’S PREMIER DIAL ENAMELER

Inflection launches with 3 dial variants in grand feu enamel, crafted by the skilled artisans in the workshop of Master 孔令俊 (Kong Lingjun) in Beijing — one of China’s finest and most renowned enamel maisons.

The enamel layers begin as a raw and unrefined mix of quartz, feldspar, borax, and other minerals that are first melted in a high-temperature furnace and then rapidly cooled in water to form glass-like fragments. These fragments are ground by hand and sieved into a fine powder that is mixed with water and applied as a paste onto the dial blanks. Extreme care must be taken to ensure that the particle size is consistent and the paste is distributed evenly, or the enamel runs a high risk of cracking.

Once the layer has been left to dry, it is then fired at temperatures between 750 and 850°C, and the entire process is repeated multiple times until the right colours are achieved. The process varies extensively depending on the format of the dial base and the colour of the dial, adding even more complexity to the enamelling process.

Once the desired colour tone is achieved, the dial is then polished down into the flat, glossy surface that grand feu enamel is revered for. Each dial has a high failure rate of approximately 50%.

The translucent, green fumé on our launch edition, 幽(Yōu), was particularly challenging to achieve and required careful balancing of multiple shades of the mineral mixture in order to achieve the even radial spread and consequent gradient that ranges from pale green in its centre to a rich viridian at the edges. Numerous trials were conducted in order to obtain the exact shades of green found in the final dial, and the hammered texture of the dial base added further difficulty to the already-complex equation.

In the case of the two permanent variants, 墨 (Mò) and 渊 (Yuān), while the creation of opaque enamel dials in singular tones might seem like a comparatively straightforward process, this is far from the case. While the outcome appears deceptively simple, the flat planar surface magnifies even the slightest imperfection, offering up no room for any flaws.

Due to the aforementioned variance in mineral composites required to achieve the individual dial colours, the enamel paste on each dial tends to react differently when fired. This often results in distortions that need to be levelled out through careful polishing — something the black dial was particularly susceptible to. Extra care was therefore necessary to achieve its uniformity, and we work closely with Kong and his team to ensure that the final dials adhere to our meticulous standards.

AN EXCITING MOVEMENT FROM A LEGENDARY WATCHMAKER

Inflection integrates a customised 03300 calibre from the Swiss luxury watch manufacture Girard-Perregaux, a movement famous for its accuracy and impeccable finishing. Girard-Perregaux's technical pedigree and capabilities in high-end finishing made them the ideal choice for the new series. As one of only a few high-end manufactures possessing the willingness and the capability to support third parties, Girard-Perregaux had also expressed their desire to foster new generations of watchmakers, and therefore agreed to support Atelier Wen and contribute to this exciting new journey.

As a manufacture with near-complete in-house capabilities, working with them opens up access to fields of decoration, artisanship and high-end finishing that Atelier Wen has never explored before. As the brand seeks to pursue the creation of better and better watches — both technically and decoratively, Girard-Perregaux’s readiness to support and contribute to the project therefore becomes a vital step forward towards that goal.

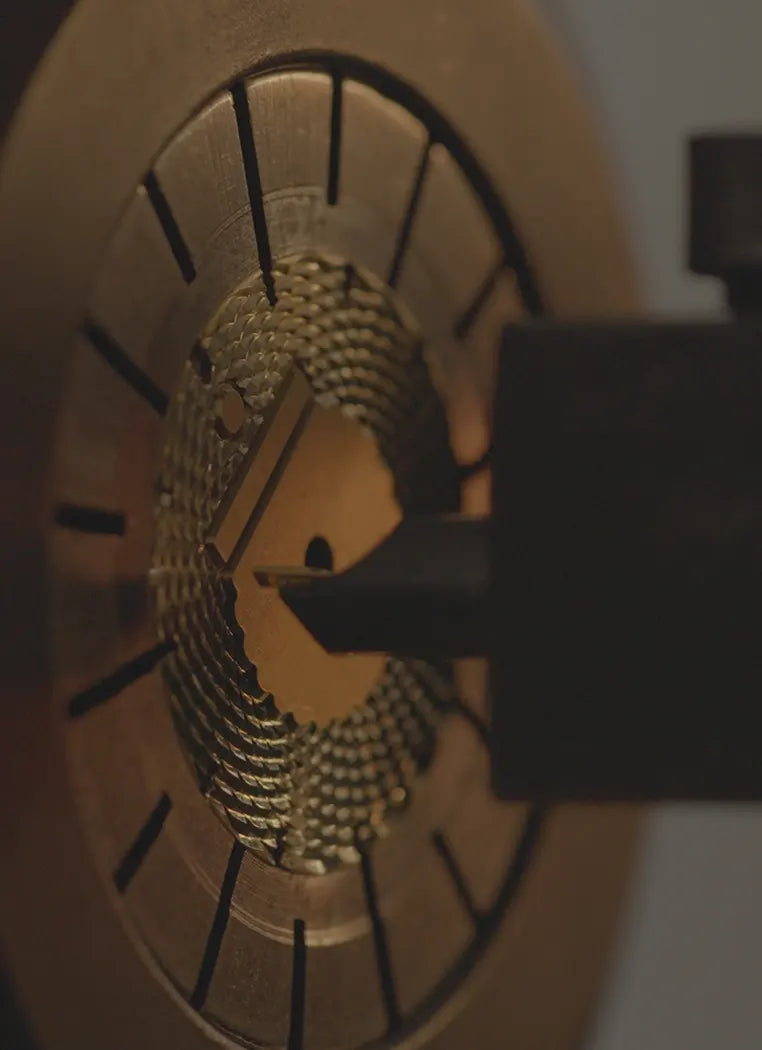

Designed by Atelier Wen’s designer, Alfred Chan, alongside Sidoine Lescauville and the Girard-Perregaux technical team, the bridges of this customised GP03300 incorporate curved, sweeping lines inspired by motifs of wind in historical Chinese paintings — chosen for their symbolic representation of the lofty material achievement that Atelier Wen has realised through our work with tantalum. These dramatic contours are split into arcing, partially skeletonised channels, giving the whole movement a unique and captivating aesthetic.

The bridges are ruthenium-plated and decorated with dramatic anglage, sharp exterior angles and laser-etched waved côtes that emanate radially from the centre of the movement, further accentuating the skeletonised channels and reinforcing the visual impression of the wind. They are held down by black-polished screws, and feature the movement’s testing standards and jewel count, as well as the Atelier Wen logo in deeply etched, rose-gold lettering.

Standing in contrast to the dark bridges, Inflection’s rotor is constructed in two parts, with a tungsten weight that is anchored to the end of five skeletonised brass spokes that have been plated in rose gold. The spokes feature the same waved côtes and anglage as the bridges beneath, and their skeletonised forms have been designed such that they align perfectly at certain positions as the rotor spins.

The calibre 03300 features automatic winding and stop (hacking) seconds, in an extra-thin profile of just 3.36mm. It boasts a power reserve of no less than 48 hours, regulated rigorously in 5 positions and to temperature, and beats at 28,800 vibrations per hour.

THE FINER DETAILS

While its unprecedented tantalum construction, handcrafted enamel dials and exceptional movement form the pillars of this flagship timepiece, they do not account for some of our characteristic attention to detail that Inflection has been imbued with.

Front and centre on its dial are Western Arabic hour markers that have been carefully printed onto the enamel surface in an original font courtesy of acclaimed designer Lee Yuen-Rapati. These draw from the aesthetic flourishes of traditional Chinese bamboo leaf painting, and add a subtle yet distinct Chinese flair to Inflection’s time-telling experience.

These hour markers are complemented by our signature leaf hands, this time executed in an altogether unexpected and noteworthy way. While most watch hands within the industry keep to within 0.1-0.2mm in thickness, Inflection’s hands come in at a whopping 0.4mm, allowing for significant volume, shapeliness and real-estate for fine-finishing. Furthermore, we elected to create specialised moulds for the hour and minute hands since the hand profiles that we had designed were impossible to create through the traditional methods of stamping. This also allowed us to create prominent, mirror-polished concavities on either side of the minute and hour hands, as well as a sharp, crisp ridge running down their middle.

This was incredibly challenging to execute upon, with watch movements being sensitive mechanical objects with minute tolerances that do not generally take well to even the smallest increments in weight. These hands were far heavier than traditional ones, and we had to therefore account for this so they did not throw off the balance of the hands and affect the efficiency of the gear train and the overall amplitude. We therefore worked very closely with Girard-Perregaux’s team to ensure that the centre of gravity on each hand was kept as close to the pinion as possible, allowing us to therefore integrate this special handset into the watch.

AN INFLECTION POINT IN OUR JOURNEY

We would very much like to think that the launch of Inflection signifies not just a pivotal moment for Atelier Wen, but potentially one in the watchmaking world at-large. Far larger brands than us have attempted to work extensively and ambitiously with tantalum, only to be thwarted by its uncooperative, unyielding nature.

For us, this achievement truly encapsulates everything that the brand has set out to do since Robin and Wilfried first dreamed up the Porcelain Odyssey back in 2018. That dream will continue to find its feet in ambitious and atypical releases, as we persevere in our goal of pushing the envelope of Chinese watchmaking ever further.

As always, this journey continues only because we can count on the watchmakers, artisans and other invaluable partners that we owe so much of our success too, as well as the unwavering support and patronage of you, our beautiful community.

Thank you, from the bottom of our hearts, for coming along with us on this journey.

Sincerely,

The team at Atelier Wen

SPECIFICATIONS

— Self-winding calibre GP03300 customised by Girard-Perregaux

— Hours, minutes and seconds

— 40mm diameter x 45mm lug-to-lug; 99.9% pure tantalum; water resistant to 100m

— 幽 (Yōu), Launch Edition — Hand-hammered 925-silver dial with fumé grand feu enamel in a radial gradient ranging from pale mint to deep viridian; white Arabic hour markers; rhodium-plated bi-planed leaf hands

— 墨 (Mò), Permanent Variant 1 — Obsidian black grand feu enamel on a 925-silver dial base; gilt Arabic hour markers; gilt bi-planed leaf hands

— 渊 (Yuān), Permanent Variant 2 — Midnight blue grand feu enamel on a 925-silver dial base; white Arabic hour markers; rhodium-plated bi-planed leaf hands

— 99.9% pure tantalum bracelet with curved links, polished mid-links, concave, mirror-polished chamfers and strong vertical brushing

— Option for sailcloth and FKM rubber strap with tantalum buckle

— USD $29,800 with 99.9% pure tantalum bracelet, and USD $19,800 with sailcloth rubber strap

**ALLOCATIONS FOR INFLECTION ARE DETERMINED ON A BY-APPLICATION BASIS.

VISIT THE INFLECTION PRODUCT PAGE HERE FOR MORE DETAILS ON THE APPLICATION AND ALLOCATION PROCESS.