Hello everyone,

It has been a long time since we have not published anything new about the development of Perception. We are fully aware that, in the last piece we had written, we stated that we would announce a significant milestone in a matter of days, yet, it had been months since this moment. Allow us to apologise for this delay; the development of this substantial “feature” proved rather complex and did take longer than expected. And you know us - if something is not 100% up to our standards, then we simply will not release it.

But, finally, here we are. This is the most significant announcement we will ever do regarding Perception. This is the core of the Perception concept, of the line’s aesthetics and of where we would like to go as a brand. Not to sound bragging, but we also believe that what we are doing is a first in the watch industry.

There it is: the dials of Perception will be true hand-made guilloché, crafted using a rose engine by the only guilloché master artisan in the whole of China and Asia. I will go into more details later about what it takes to craft a dial, but just to give you a rough idea of the amount of work required to make those, it takes Master Cheng about 8 hours to manufacture just one (1!) of them. As such availability of Perception will be highly limited.

Because of the importance of such a milestone, explanations will be split into two articles. In the first one, I will give more details about what guilloché is, who does it these days, why we decided to follow this path ourselves, and, most importantly, what it takes to make a dial. In the second post, I will provide background information about Master Cheng, our guilloché master craftsman.

What is guilloché?

What is guilloché? The craft is also referred to as “engine turning” and is the process of engraving geometric patterns into metal using a sharp cutting tool. A rose-engine machine is the tool used to carve those patterns. The art was born in the XVIth century, and debuted as a form of decoration for all kinds of objects. Because of the substantial cost of rose engines, items which were decorated using the technique were meant to be luxurious, only intended for Europe’s wealthiest. The craft first appeared on pocket watches in the late XVIIth century, and was soon adopted by Abraham Louis Breguet whose popularity gave the technique visibility and put it into the limelight. With the advent of the Industrial Revolution, it became easier to manufacture rose engines which spearheaded a wider adoption into wristwatches. Having a true guilloché dial became the hallmark of the highest-end watch brands and you can therefore find such dials in vintage Audemars Piguet, Patek Philippe and Vacheron Constantin.

Who does guilloché these days?

But if the craft is this rare, how come there are so many watches with so-called “guilloché dials” available today? You know, watches with a pattern in relief made of thin embossed lines? The answer is simple: those are not guilloché dials, but rather stamped ones trying to mimic the appearance of guilloché.

There are 3 ways of achieving “guilloché look”:

-Hand-made, rose engine guilloché: what we are doing; extremely labour intensive and less than 30 craftsman in the world. A true métier d’art. Voutilainen, Laine, Breguet, George Daniels, Philippe Dufour and RGM are other brands using this method.

-CNC guilloché: using a CNC machine to engrave a pattern into metal. This is based on the same principle as real guilloché except that it is a machine and not a human being which engraves the pattern, meaning that it is both much quicker and cheaper to make a dial. This is therefore a great cost-efficient alternative to hand-made guilloché and is currently favoured by brands like Ophion, Chronoswiss and Jaeger Lecoultre.

-Stamped dials: 99.99999% of so-called guilloché dials are made using this method. A steel mould is first created off a detailed copper master and is then used to stamp the pattern on blanks using a hydraulic press. Dials are made in a matter of seconds. Despite being cheap to produce (some of our suppliers quoted us just a few RMBs per stamped dials in case we wanted to go this way), they offer a great level of details for the price and are fitting for industrial scale production. Brands such as Grand Seiko, FP Journe, Oris, Zenith, Longines, IWC, and pretty much every names of the industry use this method.

Wonderful hand-made guilloché dial from independent watchmaker Kari Voutilainen

Wonderful hand-made guilloché dial from independent watchmaker Kari Voutilainen

Why did we decide to follow this path?

But why did we decide to follow this path? When Porcelain Odyssey was sold out and we decided to move forward with the development of Perception, we had a long reflection period and came to the conclusion that, in order to properly celebrate Chinese culture and craftsmanship like we want to do, we would need to become one of the single best Chinese watch brands. So, in a way, there is a little bit of a strategy shift vs when we created Porcelain Odyssey. We want to become one of the very best Chinese watch brands instead of just a premium lifestyle label, and Perception is somewhat of the stepping stone for this new path.

This thus means very little to no compromises in what we do, unlike with Porcelain Odyssey where we were heavily cost conscious in our manufacturing choices (e.g. Porcelain dials could have been made and painted by hands rather than in a factory). That is why we:

a. Spent long designing the series,

b. Stepped up the overall quality level significantly (e.g. 904L case and bracelet, customised super thin movement, etc.),

c. Went for a true métier d’art and did real handmade guilloché.

I guess the word is uncompromising - I feel like we need to have no boundaries in order to properly achieve our vision. In the future, we would hope to go even further in this direction: working with Chinese AHCI watchmakers to create our own movements, doing hand engravings, collaborating with top notch contemporary artists, doing grand feu enamel with the grandson of the last enamel master directly supplying the Qing court, etc. The goal is to become amongst the best, in an absolute, uncompromising way.

How is a guilloché dial handmade?

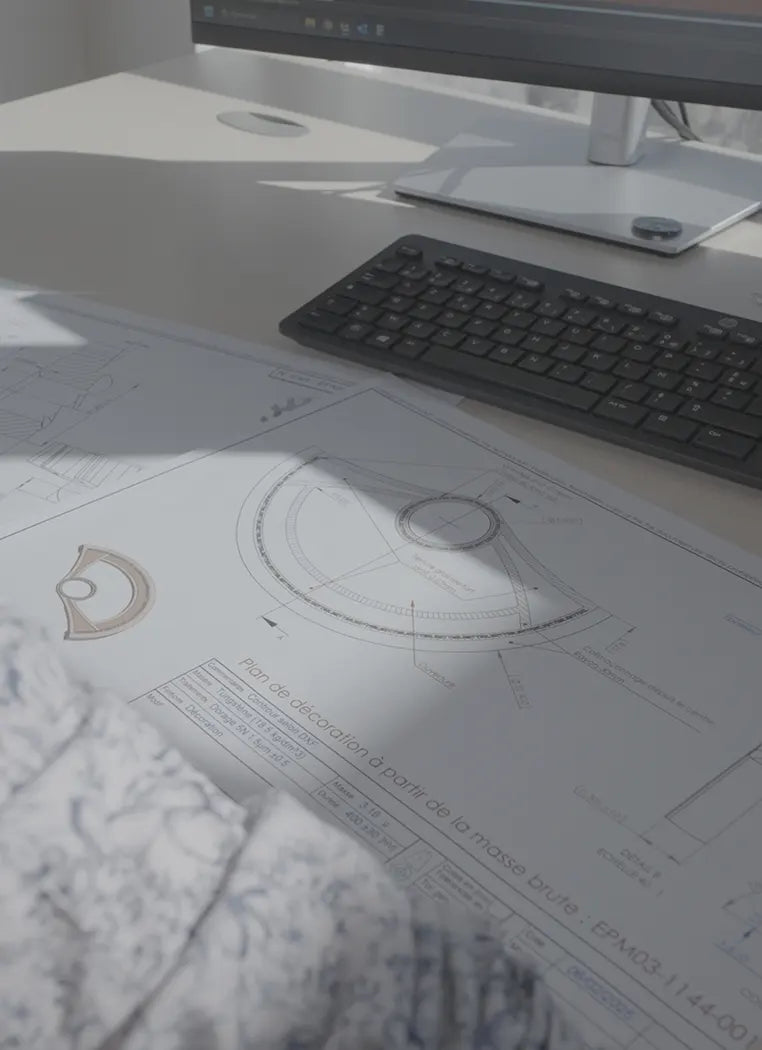

Why is it this complex to make a guilloché dial? Why does it take Cheng, our master craftsman, 8 hours to engrave just one? Here is a brief overview of the different steps which are necessary to craft a piece.

Cheng only does the guilloché. He therefore begins by receiving dial blanks from our dial blank supplier with already a cartouche delineated. As it is intended for our brand and logo, he won’t engrave there, and, as such, this is why this space is already separated from the rest of the dial. The blanks are actually made of two thin sheets of a copper alloy.

Master Cheng in his workshop

His first actual work step consists of flattening the dial blanks. It is necessary to have the flattest surface possible (up to the 0.01mm level) as parts of the dial on which a stronger pressure will then be exerted will tend to change shape. This is step is done by hands using sandpaper, and it takes roughly 5-10 minutes. In order to enhance the flatness, the dial blanks are also burnt.

Burning the dial blanks to make them flatter

Checking the dial blanks flatness

Once the blank is complete, it is installed on the rose engine and Cheng will need to find its exact centre. This is essential because engraving will start from centre and then move outwards. Even a tiny error in the centre determination will lead to a pattern that is off and unbalanced.

Installing the dial blank on the rose engine and determining its exact centre

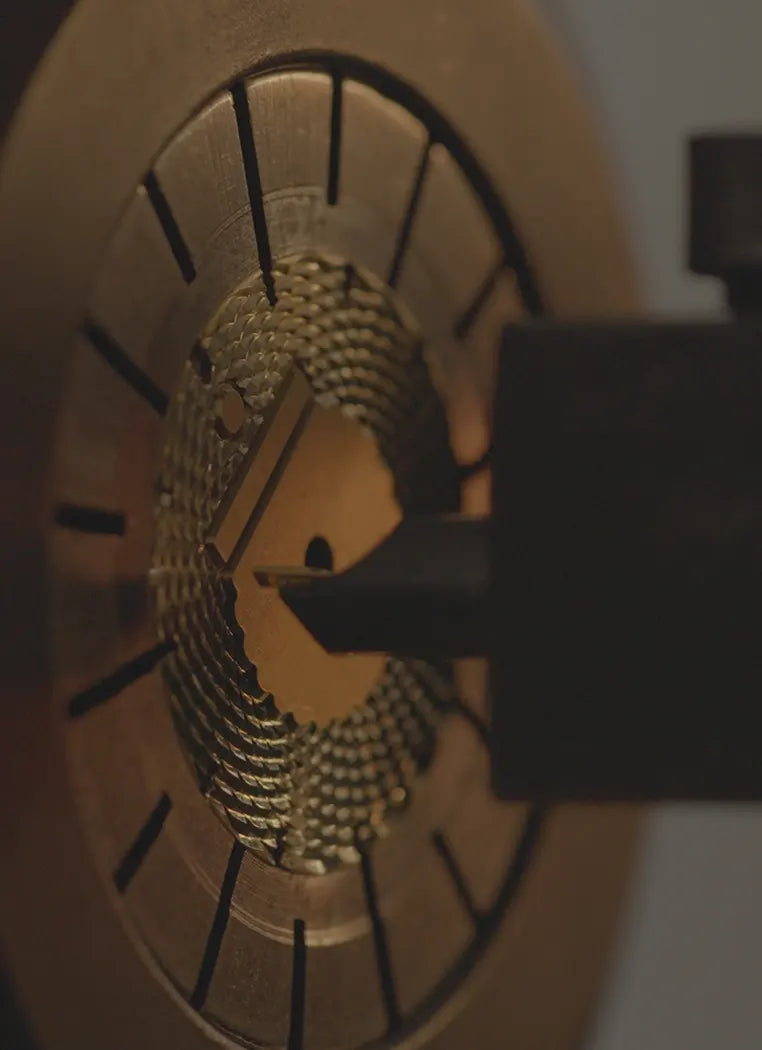

Then comes the actual engraving, which takes 8 hours to complete. A rose engine is a very complex piece of machinery. It is comprised of a large cam that rotates around an axis with a sharp tool affixed to its end, effectively mechanically engraving geometric patterns. To create the desired end pattern, different sub-patterns need to be assembled, and for that the operator will shift between the machine’s various rosettes, which are wheels of different indentation leading to different geometric sub-patterns.

The cam

The rosettes

The complete rose engine with Master Cheng

Operating a rose engine necessitates an enormous amount of skill as the craftsman will need to switch between the different rosettes by shifting the came at very precise timings (a little too late or too early and the pattern will be off) and as he/she will need to apply varying amounts of pressure throughout the process; you usually want to create some depth hence some parts of the pattern will need to be deeper while others will be shallower. In addition of finding exactly the right amount of pressure to apply at the right timing, an overall balance needs to be kept as too much pressure and it is possible to pierce through the dial blank and too little and the pattern won’t be visible enough. And if the pressure is too uneven, if there is too much variability in it, then the pattern will feel too irregular. At the slightest mistake, the dial will become scrap and Cheng will need to start again. An extreme amount of focus is needed and absolutely no vibrations are tolerated around the machine. This is why Cheng decided to install his workshop in… a cave! But more on that in the next article.

Master Cheng operating the rose engine

The sharp cutting tool engraving the geometric pattern on the dial blank

Master Cheng deeply focused on his work

The dial is then removed from the machine and polished by hands. It is burnt and flattened in order to remove all debris. It is then cleaned with water, and the final step is to dry it.

Removing the guilloché dial from the rose engine

Master Cheng checking the dial

And after all this… One, just one dial is made. Extraordinary, no?

See you soon for more details about Master Cheng's extraordinary life story.

Very best,

Wilfried and Robin