Hi everyone,

Things have been particularly hectic for the past month and a half, but we are today pleased to be sharing with you the latest production update for Perception.A long introduction

For those of you who do not want to read the long form, here is the TL;DR: due to a strict lockdown in Henan Province where Master Cheng is based, the production for guilloché dials had to be stopped for more than a month. Lots of you may be familiar with the lockdown that was put in place in Shanghai between February and August of this year, and the rules that Master Cheng faced are pretty much the same - no going out of one’s home, all businesses shut down - with the addition of all postal services also being completely interrupted. The lockdown was unannounced - we learnt about it when it came into effect - and no end date was communicated; we knew that it was over only when it was actually over.

We however did not sit idle during this period of time and worked around the clock to reduce as much as possible the delay that would result from the lockdown. We re-arranged the manufacturing chain a few times - we are at the v5 of the master Gantt chart - in order to be able to move as fast as possible when the dials would be ready, and we worked with each of our suppliers to compress lead-times for the other manufacturing steps as much as possible. As a result, deliveries for the April pre-orders have to be pushed back to before Chinese New Year (mid January). We are extremely sorry for this delay.

Now, in full honesty with you, there is a possibility the watches pre-ordered in April will be delivered before the end of the year; to be transparent, the dispatch date on our manufacturing schedule is late December. We will do everything we can to make this a reality, but as this is a tight timeline and a complex supply chain with strong interdependencies and large physical distances between each of our suppliers, we prefer to be on the safer side of things and announce before Chinese New Year. We also need to stress out that this is, of course, fully dependent on no further lockdowns being enforced, especially in the area where Master Cheng resides.

Before I close this longer-than-usual introduction, I would like to write a few words about why we did not communicate about this earlier. The reason is simple: we were completely in the dark and had no visibility on when the situation would improve. We built our manufacturing plan with chunky buffers and everyday we would witness those slowly melting. We would see all the other components being gradually completed while the number of dials was stubbornly stagnating. Calls with local contacts and authorities would invariably return the same answer: “it will be over soon.”. We did not want to cause undue panic, and therefore preferred working in silence to optimise the flawed situation as much as possible. We are, once again, sincerely sorry for this situation and we are doing our best to complete and deliver the watches as soon as possible.

A deeper look into Master Cheng's situation

Let us now delve further into the situation with Master Cheng.

When the lockdown was initiated, we were on track to deliver in the last 2 weeks of November. Actually, not a lot of dials were missing: just a few dozens were still needed and then we were meant to proceed with dial plating, dial assembly and, eventually, final watches assembly. It was thus mildly infuriating when the lockdown was promulgated, as we were so close to having all the dials.

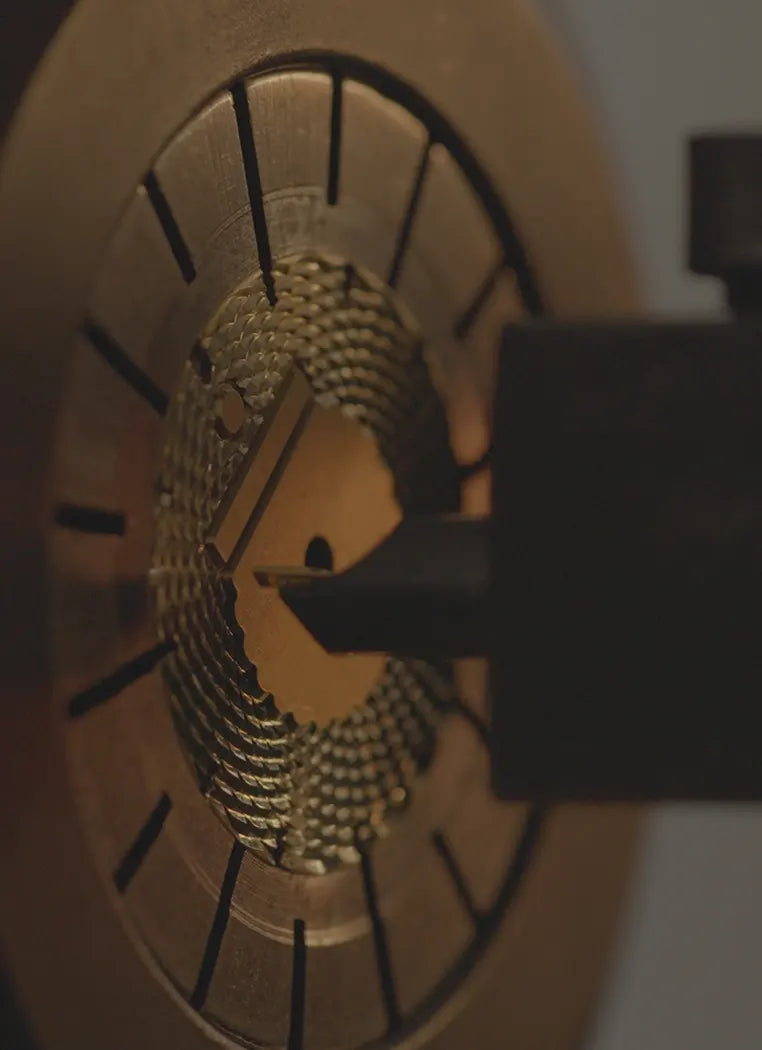

Some of you will wonder why we did not proceed with a batch approach i.e. first plating the large number of dials that were ready and moving forward with the other manufacturing steps and then taking care of the few dozens or so of missing watches. There are a few reasons behind this, but the main one has to do with how we colour our dials. Unlike 99.99% of brands out there, we do not use spray-paint but rather PVD plate them as we want to keep as much as possible of the dials’ metallic texture (otherwise we would loose part of the beauty of handmade guilloché). The thing with colour PVD plating is that you will never get exactly the same shade between 2 plating sessions. As we do not want to have colour variability between watches of the same reference, we have to plate all the dials in one go. This issue could have been avoided if we had decided to plate and produce, and deliver in colour batches (i.e. we do all the dials of one colour, and then afterwards the ones of another colour, etc.) but this would have led to other issues: quite a few individuals have ordered more than one watch and, what is more, it would not necessarily be fair in respect to the purchases order. Hence we had no choice but to wait for all the dials to be ready.

One of our suppliers suggested that we simply use some of the dials we had rejected beforehand and move forward, but that is not our philosophy at all. Sure, it would have been a quick fix that would have enabled us to forego the short-term pain of delaying deliveries by a few weeks, but, at the end of the day, Perception is a watch that is meant to last forever, and we do not want to compromise this. It felt stupid to us to destroy all our efforts and commitment to making the highest quality Chinese watch ever just to save a few days. It would not be fair to those of you who have pre-ordered Perception or who will order it in the future; we drew you to the watch based on that concept of extreme attention to details, and, in our books it would be nothing short of a lie than to ship you a product that doesn’t match fully our requirements and standards. It also would not be fair to all the talented artisans and craftsmen involved in the making of Perception and, more broadly, involved in the Chinese watch industry in general. We position this watch as the flagship of what can be made in China, and it would be completely disrespectful to ship a watch that is not at the very least 100% of what we intended it to be. It pains us to delay. We’d love to be in the situation where we can deliver on time and avoid this sort of touchy update. But as annoying as it is, we need to do it, because we are really committed to making for you the best version of Perception possible.

The end-of-year "small batch"

Regarding the small batch that was scheduled for the end of the year, this one needs to be delayed a bit further. Getting the initial 300 watches before Chinese New Year is already a big stretch due to the lockdown-induced delay. As soon as we get the initial 300 dials, all the subsequent manufacturing steps will need to be performed under reduced timeframes, and barring any further lockdowns (as I am writing these words, I have been notified that there is a new lockdown in Dandong, where our movements are made, and in Huizhou, where the packaging is produced) we will be able to deliver before this deadline (and, hopefully, starting from late December). If we were to wait for all the extra dials to be produced, we would not be able to meet this timeline, and I feel it would not really be fair to the individuals who have pre-ordered (and thus paid) more than 6 months ago.

The so-called “small batch” therefore needs to be pushed to a later date which will be after Chinese New Year. In full transparency, once again, the date in our manufacturing schedule is a little earlier than that - late February - but in order to be on the safer side of things, we prefer to announce a later completion time. Not all is negative however as delaying the delivery of this small batch enables us to increase its size, meaning that there will be more extra watches available and that, therefore, more of you will be able to get one.

After this batch is delivered, the next one should be in late Q4 2023. The manufacturing of Perception is highly complex and we want to take the necessary time to craft the next batch without having to end-up in this sort of situations.

End-of-year special edition: a clarification

At this point, we need to mention that late November a 100-piece limited edition with a third party will open for pre-order with deliveries scheduled for mid-December. The work on this project started in November 2021 and the manufacturing order was placed during Watches & Wonders, i.e. before we even began making the “regular” Perception models. The dials for this small series display a different pattern and were made at the same time as the dials for the blue, grey and salmon Perception. Dials are usually made in batches of 10-20 and the regular Perception pieces were given priority as there is, simply speaking, more of them. That being said, due to the sheer volume difference (100 vs 300), when the lockdown occurred in Henan Province, we happened to have just enough of the dials for the limited edition and be short of just a few dozens of dials for the regular Perception. Again, those were given priority and this can be seen in the fact that we had much more of them vs the limited edition dials. Despite the project only being a third of the regular Perception volume, and despite the project having began before Perception was launched, the delivery timeline was meant to be more or less the same as the one for the 300 first regular Perception pieces. Hence, please do not get the feeling that we are facing delays because of this project.

The lockdown really is what is slowing us down. We are doing our best to work around it, but when everything has to shut down, it truly freezes our operations. The area where Master Cheng lives is still at risk; nearby parts of Henan (some just a few kms away) are currently experiencing lockdown. Other parts of the country where we have operations, such as Dandong and Huizhou, are also currently under lockdown. Lots of our operations are in Foshan, and quite a few nearby cities in Guangdong are also experiencing the same situation… What I’d like say is that lockdowns are not the exception, and that most of the areas where we have operations are “at risk”.

This is pretty much it for the “painful” news. We would like to once again apologise for this delay and to assure all of you that we will be working very hard to ensure the watches will be completed and delivered as soon as possible. We also sincerely hope that no further lockdown will seriously restrict our operations. Thank you for your understanding.

Perception improvements

Let’s now move onto more positive news.

Firstly, the updated production samples have been completed and received a few weeks ago, and most of the issues that had been identified back in April are now solved. This is not an exhaustive list, but here are a few of the major improvements that were implemented: the bracelet top link now matches the width of the lugs, there is no more bad looking gap between the clasp and the bracelet, the caseback engravings are deeper and larger, the micro adjustment mechanism has been fully redesigned and is much smoother and more pleasant to use, the clasp locking mechanism has also been re-thought with a much firmer and more distinct “click”, the movement does not have a “ghost” position anymore, all the printings on the dial are very crisp, the lume on the hands and elevated chapter ring is stronger and more concentrated, the hands have more volume and are spotlessly clean, and quite a few other points!

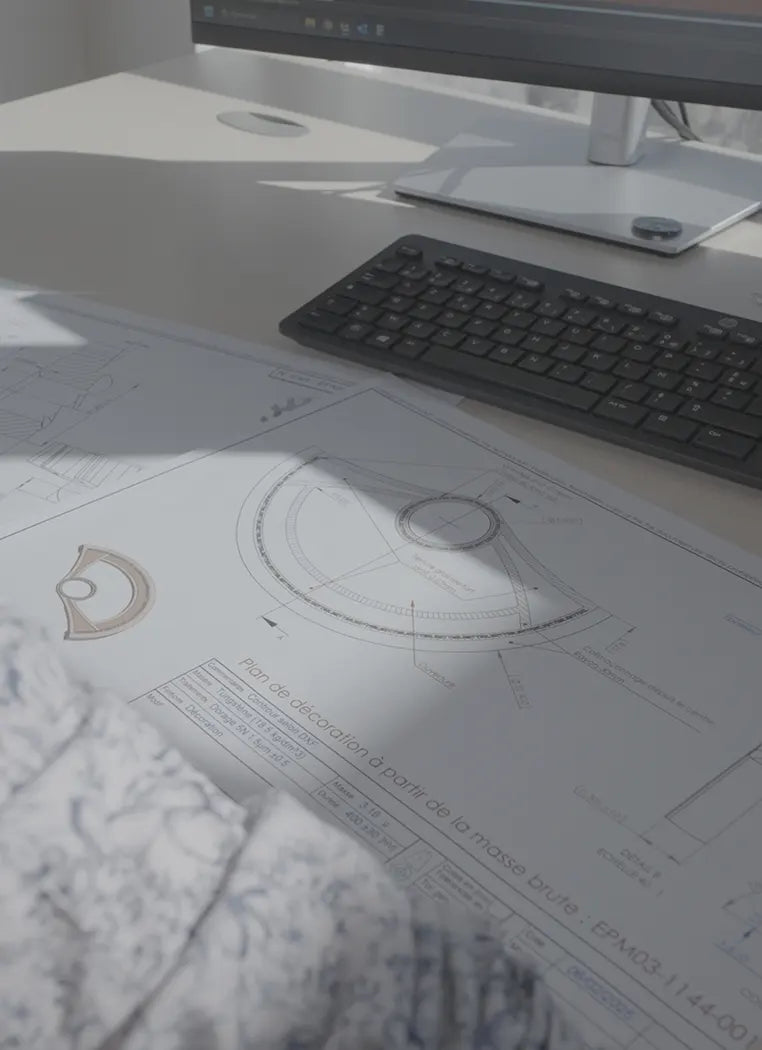

Since we received those updated samples, we also worked on some further, extra improvements which are going to be present on the final watches. The first one is the micro-adjustment mechanism button for which we have greatly improved the surface finish. Notice those chamfered angles, the strong vertical brushing and the nice textured base.

The second aspect that has been improved since we received these samples is the movement’s engravings. Well, those have actually been a long work in progress, and, while the quality level we were after had not been reached when the samples were being assembled, a few days later, we received pictures of a bridge with crisp golden engravings, finally reaching that standard we were after. Notice how clean the overall is, and how sharp the serifs are :) It would have been easy to not do any engravings at all (these bridges are hidden by the caseback), or to simply settle for the factory-standard Helvetica-like engraving font, but we wanted the attention to details to be the same all around, and therefore committed the extra effort and resources.

The first samples for the revamped packaging we had mentioned beforehand had been completed a few days ago. We are currently fine-tuning some small details, and mass manufacturing will start in the coming days. Everyone thus far who has seen or handled the sample has been quite impressed, so we really hope that you will also get to enjoy it! As a reminder, we designed this new packaging so that you would get both an elevated unboxing experience and a “useful” item that can be used on a daily basis… Stay tuned :)

October events

On another topic, we spent the last 2 weeks of October in the USA, and it was really special to get to meet so many of you in person. A huge thank you to everyone who came! During this period of time, we:

-Recorded a podcast with Wristcheck in New York, which you can watch here: https://www.youtube.com/watch?v=9KJhl1oyTro&t=3s

-Hosted an evening event with Complecto, an awesome, diversity-focused watch community in New York. It felt slightly surreal to be meeting in person some of the individuals we had been seeing on Instagram over the past few years!

-Hosted an event with Jean Rousseau, in their Midtown atelier. For the occasion, they made some leather keychains with scrap guilloché dials in the center, which we then gifted to the attendees. The idea was to repurpose some of Master Cheng’s numerous scrap dials and to give them a second life as a practical token enabling people to truly feel what guilloché can be about and therefore establish a connexion with the craftsman. Those scrap dials are untreated, so they will all age differently

-Hosted various smaller, more intimate events to really get to know our community and have meaningful, deep conversations

-Hosted an evening event in a wine bar in San Francisco with the help of 49 Crowns, a local collector group. Merci Adam !

None of this would have been possible without the help our longtime friend Jon aka @shanghai_wis and @horohands on Instagram. We met Jon in Shanghai a few years ago where he had created his own local community, Shanghai WIS (which then became RedBar Shanghai). He then moved to NYC and quickly integrated the local community. He sincerely proved instrumental in organising all these events, hence, once again, a huge thank you to Jon!

Atelier Wen was also present at the newly-established Spring Sprang Sprung in Singapore, a fair dedicated to micro brands and small independent watchmakers. It has been created by Sugiharto Kusumadi, perhaps best known as the founder of Red Army Watches aka RAW – a retailer of independent watch brands in Singapore since 2004, making him a local pioneer for independent watchmaking in Singapore.

Neither Wilfried nor myself were able to attend, but we were represented by our two good friends Justin Lam and Ignatius Tan. The 2 of them have been instrumental in Atelier Wen’s success, and we know that we owe a lot to them. To say that their job at Spring Sprang Sprung was great would be an understatement - they did more than tremendously well, and those of you who reached out to me had very positive feedback. Hence, again, a huge thank you to Justin and Ignatius!