Hello everyone,

It has been a while since our last update and we would like to apologise for the delay.

For those of you who do not want to read the following long-form, here is the TL;DR: The past two months have proven extremely busy, with Perception manufacturing almost monopolising all our resources. There are substantial challenges linked with its production, but through long hours, extra costs and the hiring of a fourth full-time supply chain consultant in Shenzhen, we are still in line with the targeted timeline. We are also happy to share that we will be hosting in-person events in the US in October as a majority of you are based there! Head to the bottom of the page for more details, and don’t hesitate to get in touch if you are interested!

Manufacturing Challenges

What exactly do we mean by substantial challenges linked with Perception production? Well, they are mostly of two natures.

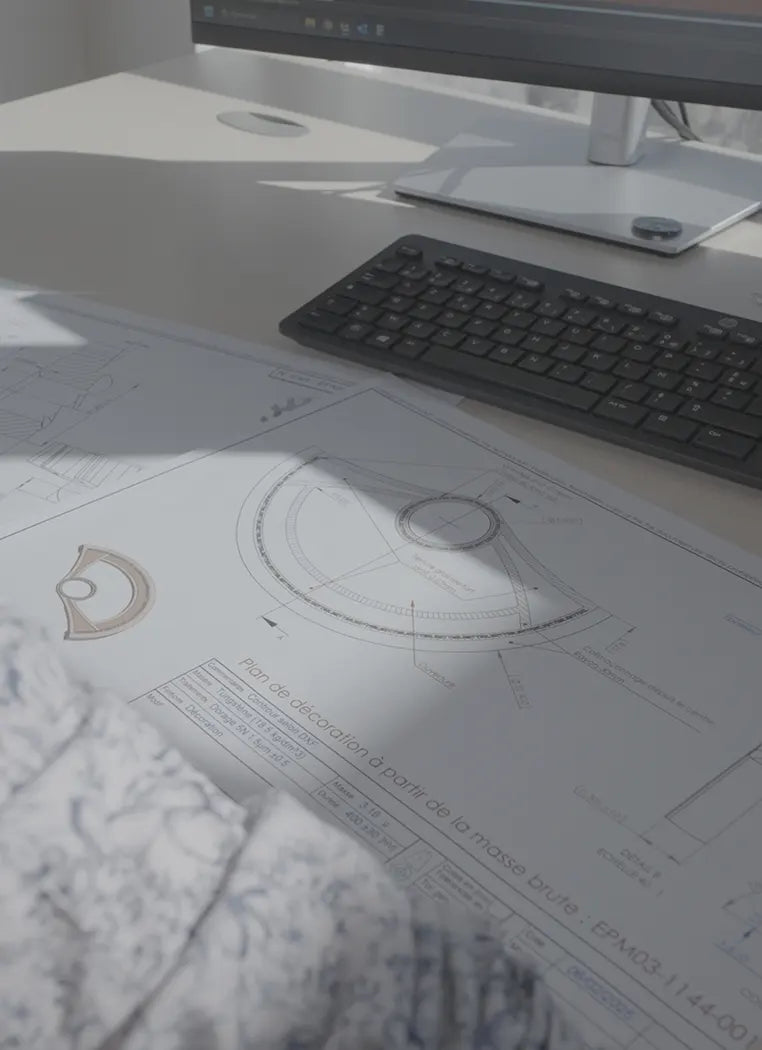

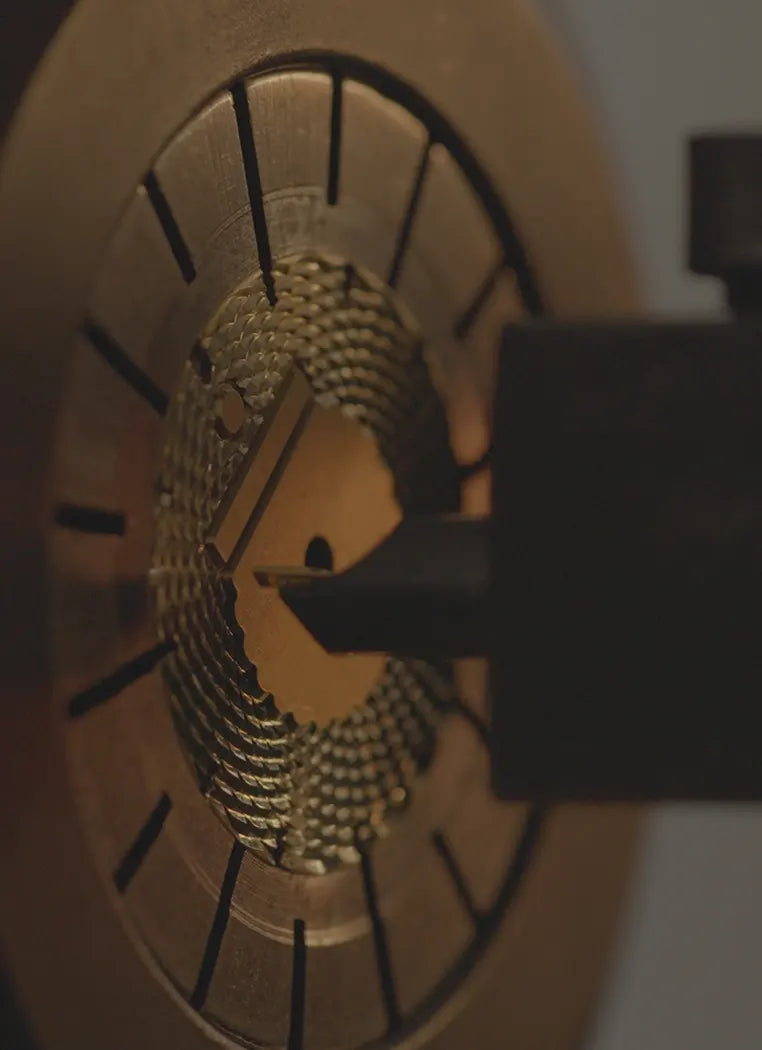

Firstly, the watches themselves are complex to make. This stems from their ambitious specifications (904L, very thin, air-tight tolerances, a large number of components, etc.), the exceptional surface finish we are aiming to achieve (sharp angles, contrasting surfaces, particularly noticeable brushing, black polishing, etc.), and, most importantly, the integration of a fully handmade component (our hand-guilloché dial) into an otherwise rather “modern” supply chain. This means differences in work organisation methods, tolerance standards and communication styles. Assembling a supply chain is a little akin to creating a sports team from scratch wherein a group strangers then need to work and collaborate together. It is easy and rather misleading to believe that suppliers, as they are each responsible for a specific component, can work independently, in silos. There are actually strong interdependencies across them meaning that, whether they like it or not, collaboration is inevitable. Difficulties arise when the ways of working are simply too different, and this is precisely what is happening in our case.

To give you an example, our case supplier works on a 0.05mm tolerance level, which is more or less the thickness of a piece of hair. That being said, this sort of standard is tough for Master Cheng to achieve as his only tool is his hand-built, manual rose engine, which is obviously quite different from a state-of-the-art Brother TC-52A CNC machine. But it also goes the other way: due to sourcing issues, our raw dial supplier had slightly changed the copper alloy he uses and this meant for Master Cheng a different resistance to his rose engine’s chisel and therefore a different, rather unpleasant guillochage experience. Despite these difficulties and occasional hiccups, all our suppliers are enthusiastic and motivated by Perception’s mission and are therefore really going above and beyond to craft a watch that you will all sincerely enjoy. In the case of the raw dials, a costlier alternative was swiftly arranged by the supplier, at his own expense. In the case of Master Cheng, he spent long hours slightly redesigning the copper raw dial to make it easier to meet the case maker and assembler’s strict tolerances and agreed to allocate, at no cost, some of his disciples and associates to manually, using a file, go over some of the “tension points” and ensure that more dials can then be used by our case maker and assembler.

The second difficulty is more straightforward: due to the current sanitary situation in China, short notice semi lockdowns are still common, and needless to say that when it happens in an area where one of our suppliers is located, it slows down the whole chain.

The key to dealing with such tough conditions is, for us, strong reactivity, which makes even more sense when the fact that any so-called “small issues” usually involves more than one party is taken into account. And this reactivity level which we are aiming for is only possible thanks to the support of our Shenzhen-based team of supply chain consultants. It initially started with 3 individuals, each of them being responsible for the relationship with a few of our suppliers. However, the various production challenges meant a substantial workload which quickly became unmanageable for the team and led us to hire a fourth person. So in case you are wondering how we are managing, this is how!

Here is a real-life example of what this strong reactivity mean. Mid-August, we faced some issues with Dandong, our movement supplier. As you may know, Perception tungsten rotor has a deep black rhodium plating, which is actually carried out by a third-party supplier and not Dandong themselves as they are only able to do gold plating. The way it works therefore is that Dandong is supposed to supply non-plated rotors, those then get sent to the third-party supplier in charge of plating, he then sends them back to Dandong and Dandong eventually assembles them into finished movements. However, due to a common misunderstanding back in May when we signed the order contract, Dandong actually started gold plating some of the rotors! Our consultants were quick to notice the issue in one of their daily supplier catch-up calls and stopped the process right in time. Thankfully, only a few rotors had been inadvertently gold-plated, and those were replaced with a batch of new, unplated rotors.

Micro-adjustment Buckle

Something we would like to update you on as well is our micro-adjustment buckle redesign. We announced in the last update that we were working on a redesign as we believed the design we had was somewhat rough with a sliding action that could feel a bit “difficult”. Well, the redesign has been fully completed over the summer and we are expecting a first sample on September 16th. We are very much looking forward to seeing them in person!

Packaging Re-design

Another point worthy of update is our packaging redesign. We were beforehand working on a rather traditional wooden box but we did not like the fact that it was likely to end up stored away, collecting dust in your closets. We thought a lot and decided that we want to deliver a superior customer experience all throughout the watch ownership process. The packaging will need to deliver an initial wow factor but we do not want this to be limited to the first unboxing. In our ideal scenario, the box would need to have another use that can be sustained on a daily basis. Our packaging supplier was excited by this new direction but did not really know what such a packaging would look like. And truth to be told, we did not either. While looking for benchmark pieces, we could not either find anything remotely similar to the vague concept we had in mind. Realising that we would not be able to figure this by ourselves, we asked an old designer friend from Shanghai for help. He studied design in Switzerland and specialised in retail displays for luxury watch and jewellery brands. We should have a completed design in 2 weeks or so, and we are extremely eager to see it!

Still on the topic of packaging, instead of pursuing printed markings for the brand and its logo inside the box, we opted for creating a high quality small metal plaque with both “Atelier Wen” and our logo engraved. Those plaques are actually made of 316L stainless steel (instead of the ubiquitous chrome-plated brass) and are horizontally brushed and beveled by hands. Each plaque receives the same attention to finish that our watches receive. This is quite important to us because we want to instil an overall brand quality standard, and as such, nothing, even the small insignificant plaques inside boxes, can be left to chance or done in a cheaper way. See for yourself:

Future Direction for Master Cheng's Workshop: The Making of China's Dial First Métier d'Art Atelier

We would like to discuss what we hope will be for you the most exciting of the news we shared. After much effort and negotiation, we are today very glad to announce that we will be able to increase, to a certain extent, production figures for Perception. Here is the full story:

As you may know, our bottleneck is currently the guilloché dial, and this heavily limits the volume of watches we are able to release. Master Cheng is already working full-time for us, and we are currently at capacity. If the fact that this volume will need to be shared with new models with guilloché dials to be released in 2023 is taken into account, the unfortunate conclusion is that there would be room only for a few dozens Perception in 2023. Though we are no Ming, Kurono or Laventure, we absolutely do not want to end up in a situation where there is an unhealthy pressure when ordering watches and when the whole process becomes unpleasant and, frankly speaking, a pain. We also do not want to attract mostly flippers. Our watches are meant to be enjoyed by collectors and not to end up a speculative commodity. Our mission is to share Chinese culture and craftsmanship and, in order to achieve this, we need to ensure a decent level of accessibility.

This therefore became a prime concern for us and as the clock was slowly ticking, we had a set of long talks with Master Cheng. We sought to understand what was driving him and, most importantly, what were his goals for the future. Because, as it is the case with a lot of activities, you rarely do things for their own sakes. Rather, there is almost always a hidden end goal behind. We thought that maybe we would be able to bring him some clarity and external opinions in his reflexion. It turns out Cheng’s goal in life is not to “just” do guilloché. He is of course enamoured with the craft, but what this means for him is that he wants to create and kickstart a new generation of Chinese craftsmen able to engine turn some wonderful guilloché pieces. He loves the craft so much that he wants to create a local scene for it. He wants enough talented craftsmen in China so that the situation he faced when he started would never repeat. He joked on the fact that this “lonely” story drew interest from all over the world but he dreams that in 10, 20, 30 years this will be just a memory and that there will be some globally recognised Chinese guilloché master craftsmen. He dreams that some of these next generation craftsmen will, one day, be held in the same esteem that the Voutilainen, Benzinger and Murphy of this world enjoy.

Cheng has had disciples for quite a few years now who have been tirelessly following his teachings. What we mean by this is that they agreed to live with him in the mountain and to wake up everyday around 5am to practice until dusk. Operating a rose engine requires a great amount of continuous focus and doing so for an entire day is sincerely tiring. Those associates who engaged in this journey have a huge amount of grit, perseverance, passion and talent. Following the various discussions we had over the summer, he agreed that his longest-serving and therefore most experienced disciple was now ready to turn dials on his own, and we of course welcomed this news with great joy and pride. The direction Cheng would like to give to his workshop is similar to a local version of famous Comblémine. He wants to train, develop and assemble a team of extraordinary craftsmen hand producing China’s most spectacular métier d’art dials. This is a huge development and step forward for the Chinese watch industry, and we are extremely proud to be supporting him.

None of this would have ever been possible without you. You are quite literally the ones who made this happen. Master Cheng used to deal with order volumes between 5 and 10 dials and for the first time in his career this figure jumped to a few hundreds. You made his order book skyrocket, and you gave him the capacity and the means to expand. You gave him the opportunity to follow a path towards achieving his dream.

USA In-person Events: See You in October!

As mentioned in the introduction, we will be hosting in-person events in the USA in October! A majority of you are based there, and following the great feedback we got for the HK and Singapore meet-ups we held back in April, we decided it was fair to reiterate the experience in the US. Here are the tentative dates and locations:

-October 17th - October 26th

-NYC and San Franciso

We are looking at hosting various gatherings. There will be a larger cocktail event with capacity for c. 30 of you, a more ”intimate”, one-to-one dinner/brunch for 10-15 of you and presence at different watch collector club meet-ups.Those will be great opportunities to see the watches in person, and chat with us :) If you have ANY suggestions, please get in touch!

More details will be circulated in the days/weeks to come, including RSVP forms, and we can’t wait to be meeting you!

Thank you.

See you soon,

--

Wilfried & Robin

PS: And please don't forget to join our exclusive WhatsApp group if you do not want to miss any further updates!