Hello everyone,

It has now been slightly over a month since we launched Perception, and what a month it has been. Today, we are very pleased to be sharing with you all the first Perception production update, highlighting everything we have been up to since April 18th. It is rather comprehensive, so sit back, and enjoy the read!

First of all, we would like to apologise for the time it took us to publish this update. We would have wished to do it sooner, yet given the large amount of work required immediately after the launch, we found ourselves with no time to draft the entry. In a way though, this was a necessary evil to achieve a greater good as pretty much all our post-pre-order work was focused on improving Perception’s quality. The breadth of upgrades we will be implementing is actually fairly wide, so we are sincerely hoping the extra quality will largely balance the update’s delay.

We would like to say a few words regarding the launch. In all honesty, it took us a few days to realise and properly comprehend that all the watches had been sold out in just 16 hours. In an era of hype and waiting lists, I know this may sound like false modesty, yet consider this: it took more than 1.5 years to sell out the complete Porcelain Odyssey range. The chasm between the two timelines is vertiginous, so much that for the immediate few days following the launch, it all felt rather surreal and abstract to us.

The second feeling which immediately materialised is one of gratefulness. We are incredibly thankful to all of you who supported Perception, Atelier Wen and our mission to celebrate Chinese culture, craftsmanship and Watchmaking with a capital W. We received countless messages of individuals congratulating us or simply expressing support for our endeavour; the fact that so many of you were rooting for Atelier Wen was exceedingly nice and moving. We have no way to compare our situation with the one of other brands, yet I am convinced that our community is really exceptional. When going through the orders, it felt nice to see both familiar names and new ones, underlying the continuous support of our early backers and the fact that the community keeps on growing. There is an increasingly high number of you sharing our vision and part of this journey, and this is truly meaningful. From the bottom of our hearts, thank you very much!

Yet not everything was rose-tinted. We were lucky enough to have many journalists kindly cover Perception, and we are deeply grateful to them - our sincere thanks to all journalists who have decided to give us a platform to share our vision. However, in some of the articles, a number of unacceptable reader comments could be found, which surprised and disgusted us. It genuinely saddens us to realise that we live in a world where there are individuals who expect everything from China to cost $5 and to be made to really shoddy standards. We were also shocked by how quickly an item as innocent as a watch, which furthermore is advocating for culture and artisanship celebration, was politicised. This nevertheless makes our mission and endeavour even the more meaningful. We will keep on making increasingly cooler watches, and we will keep on doing our best so that these individuals eventually face the stupidity of the stereotypes they hold.

Our most pressing task following the launch was to take care of the improvements to be implemented in the production Perception. While this may seem rather straightforward at first glance, the whole mission is actually made up of several sub-tasks which can, each of them, be quite difficult and time-consuming.

The first step was to define the issues. There are actually two sorts of issues: the “true” issues, which need to be corrected and the aspects which, although not problematic, could be executed better. The latter requires a more holistic thinking and can be challenging because defining a quality threshold is not straightforward; it is always possible to do “better” (whatever that means), yet the question is from what level will we consider ourselves satisfied?

The issues were brought to our attention through different channels. The first and most obvious one was our continuous wearing of the prototypes since February. Some were spotted immediately upon delivery (e.g. the width gap between the lugs and the bracelet) while others necessitated days of wrist time to be noticed (e.g. the sharpness of the angles of the clasp blades). This gave us a good overall view of the situation; after wearing the prototypes for 2 months, we estimated that they were 90% there.

We were not the only ones who have had the chance to wear the prototypes. Various journalists, supporters and friends of the brand also did enjoy a bit of wrist time, and although this was more for marketing purposes, they still gave us a host of feedback which was especially valuable as they approached the pieces with a fresh eye and were not stuck in the kind of micro paralysis we ended up in after two months of scrutinising the watches. Special thanks to Justin Lam who provided extensive and sincerely valuable feedback.

Public comments on Instagram, YouTube, watch forums and on various media also helped a lot. Comments trashing the dial quality under 30x magnification in the WatchFinder video, although harsh, actually acted as a wake-up call and forced us to put some of the finishing issues high on the agenda.

The last way we used to define these issues was probably the most radical one. I went to spend two days with our Europe after-sales watchmaker, Tristan Ledard, in his workshop in Brittany. Before I give some insights about the work we carried, let me quickly introduce Tristan. He is an extremely talented young independent watchmaker, who graduated from the Paris Watchmaking School. He has previously worked with Roger Smith on the Isle of Man, and, in 2016, he won the AHCI Young Watchmaker competition where he introduced Astro, the very first clock in the world with a linear equation of time. For those of you unfamiliar with the AHCI, it stands for Académie Horlogère des Créateurs Indépendants which means “Horological Academy of Independent Creators”. It is an academy bringing together the world’s best independent watchmakers and amongst its 35 members, you will find François-Paul Journe, Philippe Dufour and Kari Voutilainen. Saying that Tristan is a talented watchmaker is an understatement.

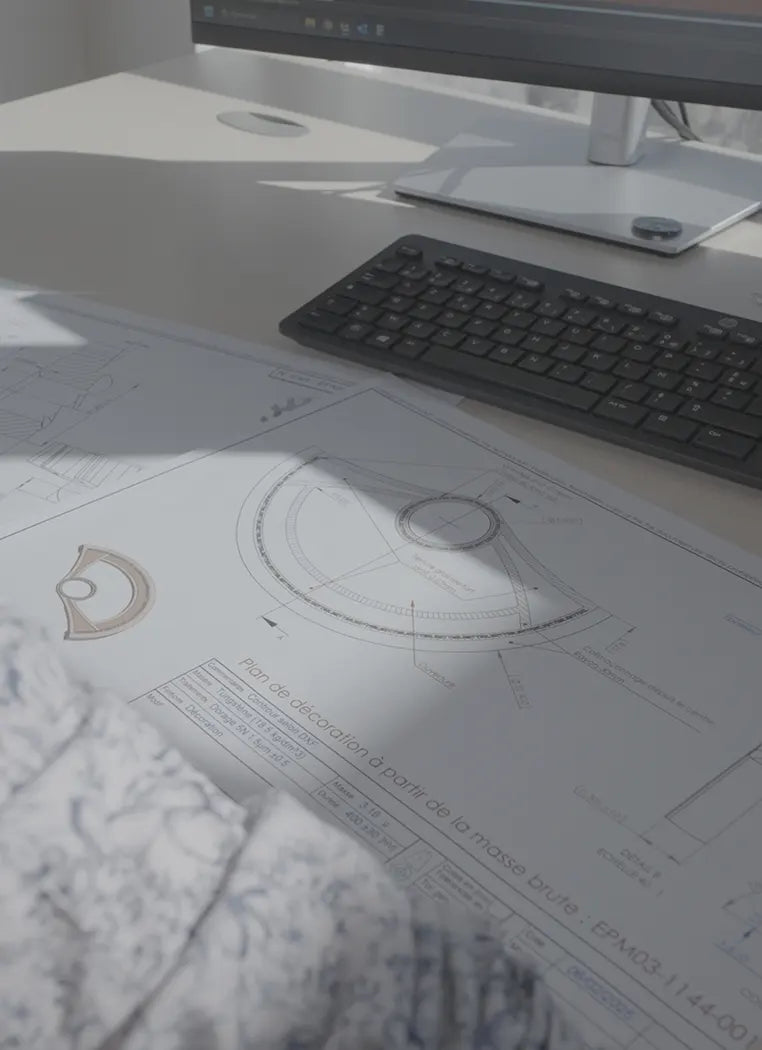

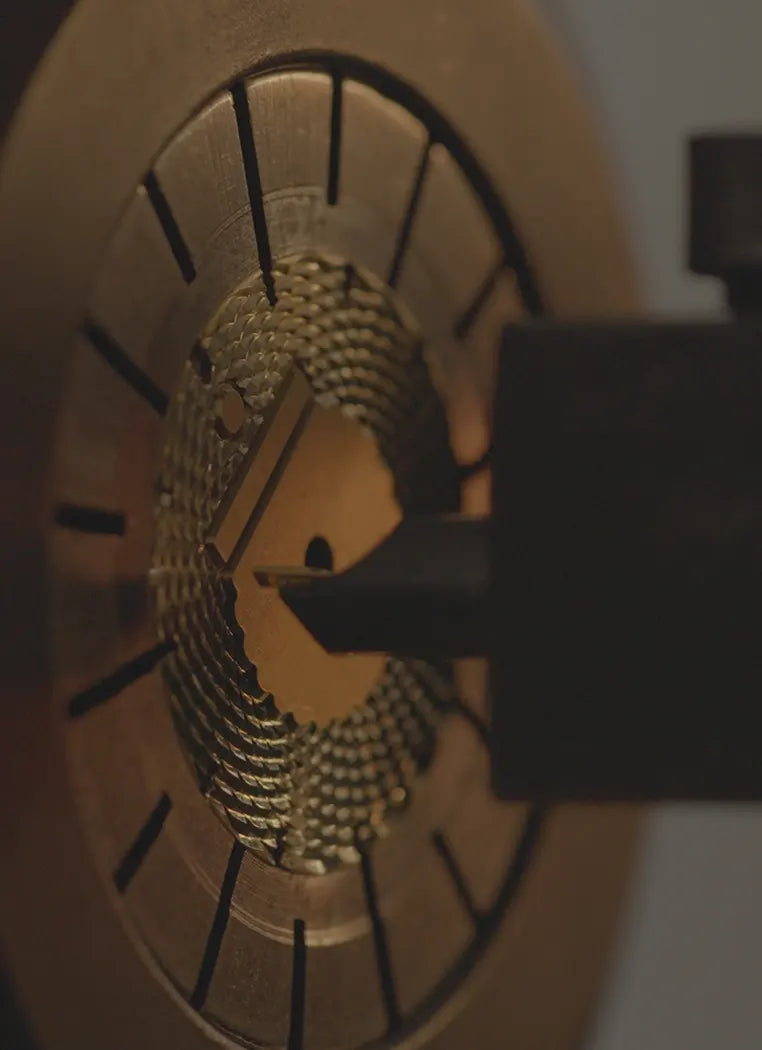

During these 2 days, we placed two prototypes under a microscope and scrutinised every millimetre of the watches under 50x magnification. We took pictures of EVERYTHING which seemed even remotely off and collated our observations into a 40-pages document. It was brutally exhaustive. It was also brutally precise. Beforehand, the issues we had identified based on the previous channels were often too vaguely defined. For instance, one point we had observed after WatchFinder released their video was that the cutouts for the indexes were “rough”. But what does “rough” mean? The shape? The surface finishing? The tidiness? If we had gone to our suppliers with ill-defined issues like that, it is likely they would not have been able to do much. In the case of the cutouts, thanks to the microscope magnification we were able to witness that the perceived roughness was coming from a rather irregular, not straight cut and from metal debris. More precise, right? As we wanted to leave nothing to chance, we figured it was the best way not to miss anything and to go past our perceptions of what needed to be improved.

The benefit of working with talented watchmakers is that, in addition of identifying issues, they are also often able to solve those. Tristan therefore helped us in finding solutions to most of the issues we had identified. This is actually not that easy. For instance, to continue with the example of the indexes cutouts, we were able to come up with a 5-step solution:

1. Have smaller cutouts on the raw base plate (implying the need to create a new mould, costing roughly $2,000)

2. When doing guilloché, Cheng needs not to exclude the border of the cutouts (as he did beforehand)

3. After guilloché is done, the cutouts need to be re-machined using CNC in order to be of the correct dimension. The use of a centring microscope is necessary to correctly position the dial.

4. Afterwards the cutouts inner sides are polished by hand using a file

5. Lastly, everything is cleaned using pumice powder and afterward an ultrasonic cleaning machine

And this is just for ONE issue. There are more than 30 of them. The solution drafting work therefore took quite a long time.

With the list of issues and suggested fixes now complete, the next step was to approach our suppliers and communicate those to them. As feared though, it was a nightmare. Pretty much all the improvements we were asking actually required complex solutions adding extra steps to the manufacturing processes, often making it necessary to have new sets of moulds and calling for skill-wise difficult and time-intensive steps. We were also asking for a high number of extra hand finishing touches and for what they deemed to be insanely low levels of tolerances (one of our suppliers repeatedly told us that it is unfair to scrutinise a watch under 50x magnification and to base our standards on what we see then). Most of the suppliers did not understand why we wanted to have the manufacturing complexity levels leapfrog just to achieve less than 10% quality increase. After a week of heated negotiations, we were hitting a roadblock.

The thing though is that we could not afford not to carry out these improvements. Well, in actual facts, for most of those we could have gone by just fine not implementing them (just ask people who got to handle the prototypes), but, let me rephrase it, we really WANTED to implement them. We desired it extremely strongly. Why do we bother so much? I believe there are two schools on the concept of quality; one that is utilitarian, where quality needs to bring tangible upsides, and one that is more holistic, where quality is more like an overall philosophy. We are obviously in the second camp, and the reason behind this is that we are adamantly convinced that in order to reach the stage where we are creating superior use and value (what the utilitarians seek), we need to have a constant quality mindset. We need to have it at the core of everything we do, almost like a religion, so that then we are able to create superior watches.

Hence we needed to find a solution since leaving things as they are was out of question for us. Reflecting on our past manufacturing experience, we realised that whenever we would encounter such tough situations (the making of Porcelain Odyssey Ji blue porcelain dial was one), visiting the suppliers in person would often help a lot with making things move forward. However, with the current health situation, entry into Mainland China is technically impossible for non-nationals.

We therefore decided to hire a local supply chain consultancy who would then act as our representative in Mainland China. The quality of Perception being the most important objective to achieve, we decided to work with a company which is mainly serving Fortune 500 clients. Needless to say that this is ending up rather prohibitively expensive but, still, as achieving our quality standards is paramount, we felt that this was worth it.

The 3-person team was dispatched across our various suppliers and started negotiating on our behalf. It turns out that the suppliers were quite concerned by the fact that although their workload and costs would increase substantially if they were to implement the changes we seek, what we had contractually agreed to pay for each component would not change. They believed it was unfair, and this is why they were not willing to move. We thus entered into some price negotiations and agreed to have the cost of almost each component increased. Those hikes are not insignificant but we believe they are worth it as those improvements will enable us to deliver Perception pieces which are aligned with our total quality mindset and overall vision and which really give justice to Chinese culture and craftsmanship. It also means that the watches you will receive will be of a higher standard than initially planned and that, hopefully, you will enjoy them more.

Those price hikes also mean that it is quite likely we will increase Perception’s retail price from USD 2,588 to USD 2,788. To those of you who managed to get one at pre-order, well, you got a hell of a deal.

All the work needed to reach the current situation and be in a position where we can produce the best possible version of Perception was, as you can imagine, time consuming. The manufacturing complexity of Perception has also been significantly heightened. Combined with an array of COVID-related restrictions still in place, you will easily understand that we will have to delay Perception deliveries a little bit. The plan was to initially start shipping them in October but this will need to be pushed to late November.

We could have easily chosen not to implement the extensive improvements we have identified, not to increase significantly our base manufacturing costs and not to spend large sums on manufacturing consultants. From an economic point of view, this is what would have made the most sense: we are increasing our overall spending yet not directly getting anything extra in return. Still, our vision of creating the very best Chinese watches possible and our constant quality mindset made it unthinkable for us to do otherwise. We have a strong desire, a craving to deliver Perception watches that will blow everyone’s minds.

We are, of course, sorry for the delay yet we are convinced that this extra month of waiting will be well worth it as the watches you will receive will be of a higher standard than initially planned meaning that, hopefully, you will enjoy them more.

Production is now ongoing and the supply chain consultants are in constant contact with our various suppliers in order to ensure that everything is going according to plan. We are also currently working with them to define a strict QC guidebook for each component so that as soon as they are ready they can be checked.

Thank you!

See you soon,

Wilfried and Robin